|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

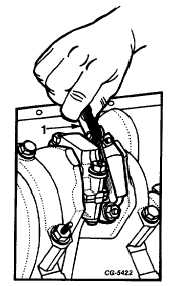

Fig. 129 Checking Connecting Rod End Clearance

1. Feeler gauge

Oil Pump Assembly

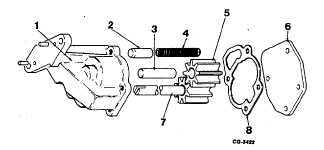

The oil pump, Figure 130 consists of two gears and a

pressure relief valve enclosed in the body. The pump is

driven from the distributor drive gear which, in turn, is driven

by a helical gear on the camshaft.

Fig. 130 Exploded View of Oil Pump

1. Body

5. Idler gear

2. Valve

6. Cover

3. Idler shaft

7. Drive shaft and gear

4. Spring

8. Gasket

The body is equipped with a regulator valve that

limits oil pressure to approximately 50 psi.

The pump intake is through a screen assembly

attached to the pump body. A mesh screen filters out

particles of dirt which may be present.

A thorough cleaning and inspection of the oil pump

should be made whenever the oil pan is removed from the

engine. The recommended inspection and repair procedures

are as follows:

1.

Wash all pump parts and screen assembly in

cleaning solvent.

2.

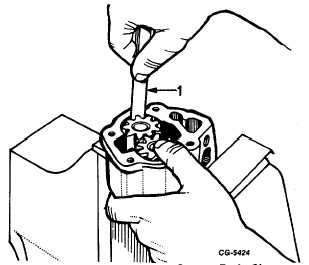

With pump cover removed and gears and shaft in

place, exert pressure against the gears with the

thumb so as to push the gears away from the outlet

side of the pump.

3.

While holding the gears in this manner, measure the

clearance between the outside diameter of the gear

and the bore of the housing, Figure 131. Clearance

should be within the limits given in the specifications.

Fig. 131 Measure Pump Gear-to-Body Clearance

1. Gauge

4.

If clearance is less than specifications, obtain new

parts.

CGES-210 Page 52

PRINTED IN UNITED STATES OF AMERICA

|