|

| |

ENGINE DIVISION SERVICE MANUAL TM 5-4210-230-14&P-1

ENGINE

However, when reboring the cylinder bore, it should

be sized to within .003" of the desired size and then honed to

provide the proper finish on the cylinder wall as well as the

correct running clearance for the piston selected.

Piston pins should be inspected and measured for

wear. If piston pins show signs of corrosion or etching or are

not within specifications, they should be replaced with new

pins. See "Specifications.' Piston assemblies furnished for

service replacement are complete with piston pins accurately

fitted.

Connecting Rods

The connecting rod and bearing must withstand

extreme forces and high temperatures. In addition, the

connecting rod and bearing are subject to changing

temperature cycles in a variety of climates and under widely

varying operating conditions.

The connecting rod bearing plays a major role in

distributing the proper amount of oil to the piston pin bearing

surfaces, cylinder walls, piston and piston rings. This is

known as oil throw-off and the condition of the connecting rod

bearing determines how well the lubrication operation is

performed.

The bearing-to-crankshaft clearance affects the

volume of oil throw-off. Where the bearing clearance is more

than specified, an abnormal amount of oil is thrown onto the

cylinder walls causing increased oil consumption and low oil

pressure due to oil passing through the bearing surfaces too

quickly. Where bearing clearances are less than the specified

amount, the oil that passes through the bearing is insufficient

to properly cool the bearing, resulting in short bearing life and

improper oil throw-off to the cylinder walls, piston pins and

piston rings. This condition contributes to scoring of pistons

and cylinder walls.

If the connecting rod bore is stretched or out-of-round

beyond the specified diameter, the insert will be out-of-round

and will not be held securely in the connecting rod since the

"crush" may be lost. Bearing failures can result from localized

bearing loads or from low oil pressure. The bearing insert

locating tangs will keep the inserts from turning in the

connecting rod bore under normal conditions but may move

and fail due to the foregoing reasons

When installing new connecting rod bore inserts, a

very thorough inspection of the connecting rod bore is

necessary. This inspection consists of the following:

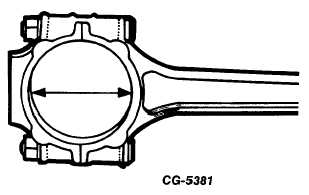

Fig. 88

1.

Bore Size: To obtain the proper bearing insert crush,

the bore must be I of a specified size, Figure 88.

See "Specifications."

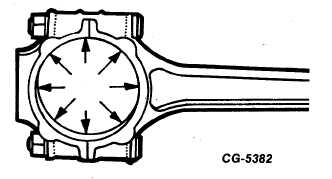

Fig. 89

2.

Roundness: The bore of the connecting rod when

assembled and the rod bolts, nuts and special

hardened washers tightened to specified torque is

round and should not exceed .005" out-of-round,

Figure 89.

3.

Surface Finish: The connecting rod bore must be

smooth, Figure 90.

CGES-210 Page 32

PRINTED IN UNITED STATES OF AMERICA

|