|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

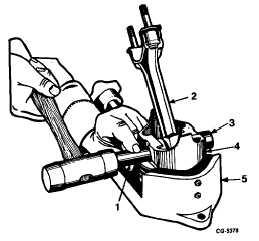

Heat piston in boiling water or piston heater and after

placing piston in vise drive pin from assembly with a suitable

remover or brass drift and soft hammer, Figure 85.

Fig. 85 Removing Piston Pin

1.

Brass drift

4.

Piston

2.

Connecting rod

5.

Piston vise

3.

Pin

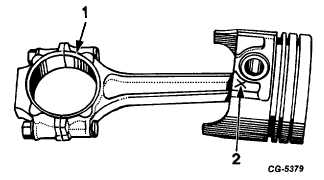

After the pin is removed, separate the piston from the

connecting rod, taking precaution to see that the parts are

marked so they may be reinstalled in their respective cylinders

unless defective.

NOTE:

Pistons should also be marked at this time

to insure they are reinstalled in the same

position on the connecting rod as they

were removed, Figure 86. Mark the

pistons so that the mark will not be

removed during cleaning operation. If new

pistons are installed, piston may be -

installed either way on the connecting rod.

Fig. 86 Mark Piston for Identical Reinstallation on

Connecting Rod

1.

Large chamfer

2.

Place mark here

Remove all old rings and immerse all parts of the

piston in cleaning solvent and clean thoroughly. Use a special

ring groove cleaner on broken piston ring to clean all carbon

from the piston ring grooves.

NOTE:

Never use a caustic solution for cleaning

aluminum pistons.

Inspect the pistons for scuffed or scored skirts or

cracked or worn ring lands, discarding any showing such

condition.

To select the correct size pistons for an engine

overhaul, the size of the cylinder bore diameters must be

determined first. This can be accomplished with the use of an

inside reading micrometer SE-686 or dial bore gauge SE-

2331. (Refer to Figure 71.) Each bore should be measured at

the top of ring travel and the lower end of ring travel both

parallel and at right angles to the crankshaft.

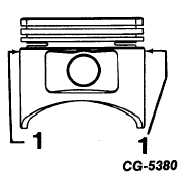

After the cylinder bores have been measured and

recorded, the next step is to select a piston to fit a certain

bore. This is accomplished by measuring the piston at the top

of the skirt across the thrust faces with an outside micrometer,

Figure 87. The size piston selected should be large enough to

permit cleaning up the cylinder bore and provide the proper

running clearance as shown in the specifications.

Cylinder blocks having deep scuff or score marks

may require reboring for use of oversize pistons; therefore, the

foregoing information still applies.

Fig. 87

1.

Measure piston at this area for fitting.

CGES-210 Page 31

PRINTED IN UNITED STATES OF AMERICA

|