|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

inder bore. Never use gasoline, kerosene or commercial

cleaners to clean cylinders. Solvents of this nature will not

remove abrasives from the walls. Rapid engine wear and ring

failure results from failing to properly clean abrasives from the

cylinders.

However, if the wear exceeds the previously mentioned

limits, it is recommended to rebore the cylinder of cylinders to

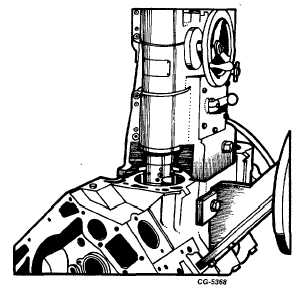

within .003" of the required oversize diameter, Figure 75. This

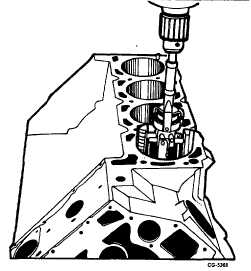

will allow enough stock for the final step of honing the bores,

Figure 76, so that the exact clearance may be obtained for the

selected oversize piston. When performing the honing

operation, the hone should be stroked up and down to

produce a crosshatch pattern on the cylinder wall as shown in

Figure 77. The faster the hone rotates, the faster it must be

stroked up and down to produce the desired crosshatch

pattern.

NOTE: After the honing operation is completed .

the sharp burred edge that develops at the

bottom of a newly honed cylinder should be

removed manually with emery cloth . Then

thoroughly clean the block and cylinder bores.

Fig. 75 Reboring Cylinder Using SE-1399 Boring Machine

Wipe as much of the abrasive deposits from the

cylinder wall as possible. Then swab out each abrasive-

coated cylinder with clean SAE-10 oil and carefully wipe it

with a clean cloth. One swabbing and wiping is not sufficient.

Three complete operations are usually required - more may

be necessary. Continue cleaning until a clean, white rag

shows no evidence of discoloration when wiped through the

cylinder bore. Never use gasoline, kerosene or commercial

cleaners to clean cylinders after honing. Solvents of this

nature will not remove abrasives from the walls. Rapid engine

wear and ring failure result from failing to properly clean

abrasives from the cylinders.

Fig. 76 Honing cylinder bore Using SE-784 Cylinder Grinder

Fig. 77 Proper Honing Leaves a Crosshatch on the Cylinder

Wall

Inspect the camshaft bearings for wear and proper

running clearance. See "Specifications." If the limits are

exceeded, replace the bearings. This can be accomplished

with the special camshaft bearing remover and installer SE-

1897 with two SE-1897-7 adapters and the slide hammer and

adapter from puller set SE-1879.

NOTE: Oil holes must be in alignment with holes

in the crankcase.

1.

Position one adapter SE-1897-7 in the second bearing

with the flange to -ward the rear of the block, Fig. 78.

CGES-210 Page 28

PRINTED IN UNITED STATES OF AMERICA

|