|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

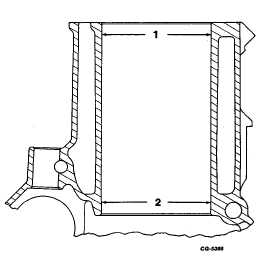

Fig. 72 Checking cylinder Bore Out-of-Round

1. “A”

2. “B”

Fig. 73 Checking Cylinder Bore Taper

1. "A"

2. "B"

If the cylinder bore does not exceed the limits of .002"

out-of-round and/or .005" taper, new standard size service

piston rings will give satisfactory performance provided the

piston clearance is not excessive.

Cylinder bore blocks can be deglazed by the use of SE-

2314-5 glaze breaker brush, Figure 74. This silicon carbide

tipped nylon flexible brush quickly deglazes cylinder walls and

produces a crosshatch pattern on the cylinder wall surface in

a single operation. The brush contours itself to the cylinder

wall and conditions the wall surface without altering the

cylinder bore.

Fig. 74 Deglazing Cylinder Wall Surface Using SE-2314-5

Glaze Breaker Brush and Electric Drill

The SE-2314-5 brush is used in conjunction with an

electric drill, Figure 74. A slow RPM drill is recommended.

Most 3/8" capacity electric drills are satisfactory for driving the

brushes. A drill speed of 350 - 500 RPM has been found to

be a practical speed for deglazing IH cylinder block bores.

A lubricant should be used with the silicone carbide-

tipped brush to produce a desirable finish on the wall surface

.

A

lightweight

engine

oil

(SAE-30)

provides

adequate

lubrication for deglazing cylinder block bores. The lubricant

also controls airborne particles which can be easily wiped

from the cylinder bore with a cloth.

When conditioning cylinder block bores, stroke the

brush up and down in the bore at a rate of 30 - 40 strokes per

minute for a duration of 15 - 20 seconds per cylinder bore. In

most instances, 20 seconds is adequate time for the brush to

break cylinder wall glaze and produce a crosshatch pattern on

the cylinder wall surface.

Thoroughly clean cylinder bore walls after deglazing.

Wipe as much of the abrasive deposits from the wall as

possible. Then swab out each abrasive-coated cylinder with

SAE-10 oil and carefully wipe it out with a clean cloth. One

swabbing and wiping is not sufficient. Three complete

operations are usually required - more may be necessary.

Continue cleaning until a clean, white cloth shows no

evidence of discoloration when wiped through the cyl-

CGES-210 Page 27

PRINTED IN UNITED STATES OF AMERICA

|