|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

10.

Remove air cleaner.

11.

Disconnect heater hoses.

12.

Disconnect wires from alternator, coil, distributor, heat

sender unit and oil sender unit.

13.

Remove engine ground strap.

14.

Remove choke and throttle wire.

15.

Disconnect tachometer cable, if so equipped.

16.

Remove accelerator linkage at carburetor.

17.

Remove fuel line at fuel pump.

18.

Disconnect exhaust pipe at manifold.

19.

Disconnect wires at starting motor.

20.

Disconnect canister vent and purge lines at carburetor,

if so equipped.

21.

Disconnect the freon compressor wire at connector.

22.

Remove the freon compressor lines at compressor.

23.

On chassis equipped with air brakes, disconnect the

main air supply line and the flexible air line at the

compressor.

24.

On chassis equipped with hydraulic brakes having a

hydrovac, disconnect the vacuum air cleaner hose at

rear of intake manifold.

25.

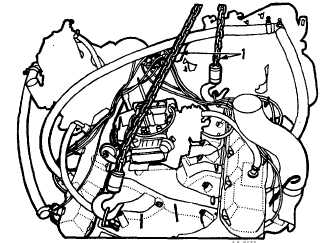

Install lifting sling, Figure 9.

26.

Connect hoist to lifting sling.

27.

Place a support under the transmission.

28.

Remove the 12 bolts securing the bell housing to

flywheel housing.

29.

Remove the engine front mounting bolts and insulators.

30.

Remove the engine rear mounting bolts and insulators.

31.

The engine must be pulled forward to clear the

transmission main drive gear and clutch driven disc;

then, raise and lift out of chassis.

NOTE: Extreme care must be exercised during removal

of the power plant to avoid damage to the clutch driven

disc and wiring harness .

Fig. 9 Engine Lifting Sling

1. Lifting sling

ENGINE INSTALLATION

Prior to installation check to be sure that all lines,

cables and parts are installed on the engine assembly that

were connected to and removed with the engine. If

maintenance was performed, be sure all adjustments affected

are made correctly. If any components of the engine were

removed and installed, check all connections and related

parts to insure the installations were accomplished correctly.

In general, the installation of the engine is performed in

the reverse order of the removal. When positioning the

engine in the chassis, special care must be exercised during

installation to avoid pinching of the wiring harness between

the engine and frame assembly.

Lower the engine to align the transmission main drive

gear spline with the clutch driven disc. The weight of the

engine assembly must be supported until the twelve bolts

securing the bell housing are installed. Connect the wiring

harness, lines and linkages that were disconnected during

removal.

Install the radiator assembly and shroud and connect

the upper and lower radiator hoses on the conventional

chassis.

On conventional chassis, install the front end sheet

metal and stay rods.

Install the hood assembly

CGES-210 Page 9

PRINTED IN UNITED STATES OF AMERICA

|