|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

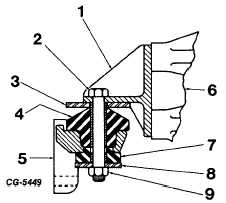

Fig. 7 Engine Rear Mounting with Two-Piece Insulator

1.

Bracket

2.

Bolt-torque to 160-175 ft. lbs.

3.

Washer

4.

Upper insulator

5.

Bracket to frame rail

6.

Flywheel housing

7.

Lower insulator

8.

Washer

9.

Locknut

CRANKCASE VENTILATION SYSTEM

The purpose of this system is to prevent crankcase

vapors from entering the atmosphere by drawing the vapors

into the intake manifold and burning them with the normal fuel

mixture. The system utilizes the vacuum created in the intake

manifold to draw clean air through the crankcase and valve

chamber. Fresh air enters the cylinder head cover through

the flame arrestor by route of the connecting hose from the air

cleaner. The flame arrestor must be serviced at intervals

according to the "Operator's Manual."

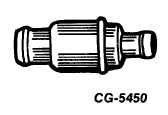

The crankcase ventilator valve, Figure 8 located in

the right cylinder head cover varies the air flow through the

crankcase to meet changing conditions at all engine speeds

and loads. The system will work effectively as long as all

component parts are clean and free from sludge and foreign

material.

The valve should be serviced and the system

inspected and cleaned at intervals set forth in the "Operator's

Manual." It may be necessary to inspect and clean the system

more frequently under adverse driving or weather conditions.

To check the operation of the system, first remove

the valve from the cylinder head cover; then with the engine

operating, a vacuum should be felt at the end of the valve. If

no vacuum is present, the valve, hose and fitting should be

removed and cause of the restriction determined. The inner

chamber of the valve should be checked by inserting a stiff

wire into the valve body to see that it can be moved freely.

Upon reinstallation, the crankcase ventilation valve should be

installed as indicated on the valve by an arrow.

Fig. 8 Crankcase Ventilator Valve of One-Piece Construction

The oil filter cap is non-vented, and therefore,

requires no service.

ENGINE REMOVAL

Engine removal procedures will vary between vehicle

models and also between individual chassis because of

various equipment and accessories. The following outline

covers, in general, the engine disconnect points and lifting

instructions.

Preliminary Instructions

1. Remove front bumper, if equipped with steel hood.

2. Raise hood.

3. Disconnect battery cable from battery.

4. Drain radiator and engine block. See Figures 2 & 3 for

location of engine coolant drain cocks.

5. Drain oil from engine oil pan.

6. Remove hood assembly.

7. Disconnect shutter cylinder air line, if so equipped.

8. Disconnect radiator hoses.

9. Remove radiator support and core assembly (fiberglass

hood only). If equipped with steel hood, disconnect

headlamp, etc., wiring at cowl and remove radiator

support and core assembly with fenders and splash

panels as an assembly.

CGES-210 Page 8

PRINTED IN UNITED STATES OF AMERICA

|