|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

Connect the battery ground strap and fill the cooling

system to the specified level. Fill the engine crankcase with

specified engine oil to the proper level. Refer to the

Operator's Manual for this information. However, if equipped

to prime the lubricating system, refer to "Lubrication System

Priming" and follow the procedure described.

Check accessory and pulley drive belts and adjust if

necessary.

Start engine and operate all controls through their full

range to check for proper adjustment.

Inspect all hose connections for coolant leaks and air

connections for air leaks.

ENGINE DISASSEMBLY

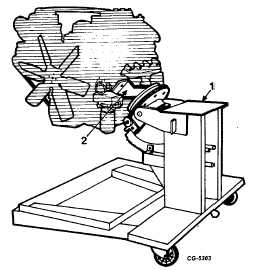

Install the engine in the SE-1962 Overhaul Stand with

mounting plate, Figure 10.

Fig. 10 Engine Installed in SE-1962 Overhaul Stand With

Mounting Plate

1. Engine stand

2. Mounting plate

NOTE: Use of this overhaul stand permits raising or

lowering (vertical to horizontal position) the engine as

required to permit rotating the engine 360°

and is held

securely in any of the eight positions provided . However,

before engine rotation is performed, it is recommended

the engine be stripped of as many components as

possible to eliminate excessive weight and provide

clearance. The engine can be raised in a vertical position

over the pedestal of the stand and the pin released and

crankcase rotated and locked in any one of the eight

positions.

1.

Make sure all oil and water have been drained from the

cylinder block.

2.

Remove fan blade with spacer and front engine mount.

3.

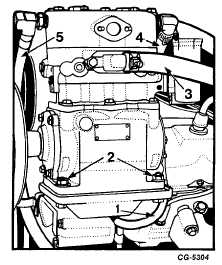

Disconnect water inlet, water outlet, air inlet and oil

feed lines from air compressor, Figure 11.

Fig. 11 Air Compressor Removal

1. Oil feed line

4. Water inlet line

2. Nuts

5. Water return line

3. Air inlet line

4.

Loosen four nuts on bracket and slide compressor

inward, Figure 11. Remove V-belt and water pump

front pulley.

5.

Remove nuts, bolts and flat washers from bracket and

remove air compressor with gasket. Remove water

inlet and outlet hoses.

6.

Remove

bolts

and

lockwashers

securing

air

compressor bracket to the engine, Figure 12. Remove

bracket with "O" ring.

7.

Loosen alternator adjusting strap bolt and mounting

bolt, Figure 13. Remove two V-belts.

8.

Remove alternator adjusting strap bolt and mounting

bolt with flat washers. Remove alternator from bracket.

9.

Remove alternator bracket and adjusting bracket by

removing bolts and flat washers, Figure 14.

CGES-210 Page 10

PRINTED IN UNITED STATES OF AMERICA

|