|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

ENGINE LUBRICATION PRIMING

When assembling the overhauled engine, it is

necessary to thoroughly lubricate the various running parts

with clean engine oil to assure initial lubrication when engine

is first started. However, to further make certain that

complete initial lubrication is available, the engine lubricating

system should be pressure primed or charged with oil. The oil

leak detector, SE-1632, can be used for this purpose. Attach

the line from the oil leak detector to a suitable fitting such as

the main oil gallery plug located on the left side of the

crankcase. Inject sufficient oil into the engine to fill the oil

filter and charge the entire system. Use only clean engine oil

of the grade to be used for engine break-in. New or

overhauled engines that have been in storage over an

extended period should also be primed in a similar manner.

In addition to priming engines that have been stored, the

engines should be turned over a few times while being

primed.

NOTE: Disconnect the coil primary wire

when performing this operation to prevent

the engine from starting.

When the priming procedure is used, make certain

the oil level is checked before the engine is put into service.

Caution should be taken so as not to overfill or have

insufficient oil as a result of using the pressure priming

procedure.

Priming the engine will minimize the possibility of

scuffing or heat buildup in the areas of friction, which could

lead to immediate or eventual failures.

OIL FILTER (Spin-On Type)

Replace the oil filter by using the following

procedure:

1.

Remove

oil

filter

assembly

by

turning

counterclockwise with the hands or a suitable tool.

Clean the filter mounting pad.

2.

Coat the gasket on the new filter with a film of

grease.

3.

Place the new filter in position on the center tube.

Hand tighten 1/2 to 3/4 turn after the gasket first

contacts the base of the mounting pad.

4.

Start engine and run for at least five minutes to warm

oil and check for leaks. Also check engine oil level.

ENGINE MOUNTINGS

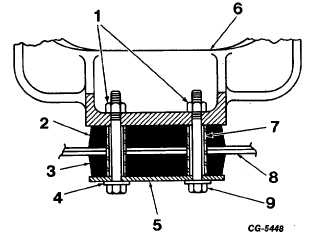

Engine mountings may vary between vehicle models.

The mountings illustrated are both of the two-piece insulator

type.

Front Mountings

The engine front mounting shown in Figure 6 utilizes

a two-piece insulator with sleeves. When assembling,

position component parts as shown and tighten hex head bolt

to 75 to 85 ft. lbs.

Fig. 6 Engine Front Mounting with Two-Piece Insulator

1.

Tighten to 75 - 85 ft. lbs. torque (threads lubricated)

2.

Insulator- upper

3.

Insulator - lower

4.

Hardened washer

5.

Retainer

6.

Engine mounting bracket

7.

Sleeve

8.

Crossmember

9.

Bolt

Rear Mountings

The engine rear mountings shown in Figure 7 also

utilizes a two-piece insulator. When assembling, position

component parts as shown and tighten nuts to 160 to 175 ft.

lbs.

CGES-210 Page 7

PRINTED IN UNITED STATES OF AMERICA

|