|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

Fig. 8 Effects of Turbulence Burning

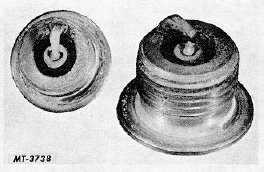

Wet Fouling

Wet fouling,shown in Fig. 9, illustrates that the plug

has drowned in excess oil. In an old engine, suspect worn

rings or excessive cylinder wear. In OHV engines too much

oil may be coming in past the valve guides. Also, depending

on cylinder location, this fouling can suggest a leaking

vacuum booster pump diaphragm. Use of a hotter plug may

relieve such fouling, but plugs can't take the place of needed

engine overhaul. Remember that plug fouling in new engines

may occur before normal oil control is achieved. In new or

recently overhauled engines such fouled plugs can be cleaned

and reinstalled.

Fig. 9 Wet Fouling

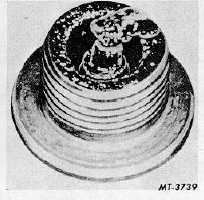

Silica Deposits

Silica deposits, illustrated in Fig. 10, are hard and scratchy.

This material is largely lead silicate formed when fine sand

particles (silicate) combine with the anti-knock compounds in

the fuel. It's most common in trucks operating in dusty areas

or in sand loading operations. Such plugs cannot be cleaned.

Always check for intake manifold leaks and see that the air

cleaner on the engine is in good condition.

Fig. 10 Silica Deposits

Fuel Scavenger Deposits

Fuel scavenger deposits shown in Fig. 11 may be

white or yellow in color. They may appear to be bad, but this

is a normal appearance with certain brand fuels. Such

materials are designed to change the chemical nature of

deposits

to

lessen

misfire

tendencies.

Notice

that

accumulation on the ground electrode and shell areas may be

unusually heavy, but the material is easily flaked off. Such

plugs can be considered normal in condition and can be

cleaned with standard procedures.

Fig. 11 Fuel Scavenger Deposits

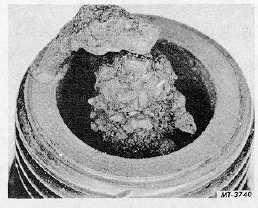

Sustained Preignition Damage

Sustained preignition damage, illustrated in Fig. 12,

usually involves melting of the ceramic firing tip. Since this

requires temperatures about 2700°F, other components of the

engine may also have been damaged by preignition. This is

another sure sign that a careful inspection of the engine and

its adjust ments is required.

CTS-2016-J Page 5

PRINTED IN UNITED STATES OF AMERICA

|