|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

Fig. 12 Sustained Preignition Damage

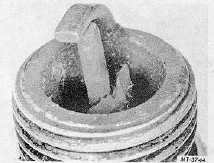

Chipped Insulator

The chipped insulator shown in Fig. 13 results from bending

the center electrode during regapping of the plug. Under

certain conditions severe detonation can also split insulator

firing ends. Obviously, the plug must be replaced.

Fig. 13 Chipped Insulator

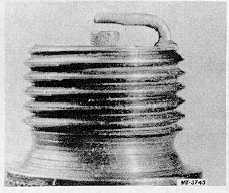

Mechanical Damage

Mechanical damage to plug shown in Fig. 14 is caused by a

foreign object in the combustion chamber. Small objects can

travel from one cylinder to another (because of valve

overlap). Be sure to check the other cylinders to prevent

recurrence of damage. When working on an engine, be

certain the carburetor throat and spark plug holes are kept

covered.

Fig. 14 Results of Mechanical Damage

Reversed Coil Polarity

Reversed coil polarity can often be detected by "dishing" of

the ground electrode. Note in Fig. 15 that the center

electrode is usually not worn badly. This source of misfiring

and rough idle can be corrected by reversing the primary coil

leads.

Fig. 15 Reversed Coil Polarity

Spark Plug Gap Tools

Pressure-type (plier) gap tools, if improperly used, impose a

tremendously high unit pressure on the center electrode (Fig.

16). This is because of compression being exerted between

the end of the center electrode and the top of the shell. If too

much force is applied through leverage multiplication, the

center electrode seal on any type or brand of spark plug is

likely to be damaged. The conventional type gap tool, which

should only contact the ground electrode, is less likely to

damage the plug.

Fig. 16 Damage to Spark Plug from Pressure (Plier)

Type Gap Tools

Condition of Electrodes

The extent of service and mileage to which a spark plug has

been subjected is generally best indicated by the degree of

wear of the electrodes, Fig. 17. When the center electrode

CTS-2016-J Page 6

PRINTED IN UNITED STATES OF AMERICA

|