|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

Clean cable terminals and apply a light coat of

lubricant/sealer (IH part number 472141-C1) of terminals at

assembly. Make sure cables seat properly on distributor cap

and spark plug terminals and in coil tower terminal.

Be sure ignition cables are routed correctly. Proper

routing of cables must be maintained to prevent crossfire.

PRIMARY VOLTAGE DROP TEST

This test can be used to help locate any high

resistance or loose connections in primary feed circuit

between the battery and the ignition coil positive (+) terminal.

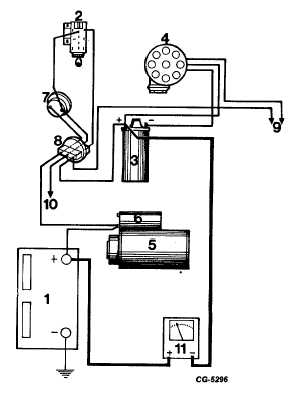

Test Procedure (Refer to Figure 58)

1.

Remove distributor cap, rotor and shield. "Bump"

starter to position sensor coil between two trigger

wheel teeth.

2.

Connect voltmeter positive (red) lead to battery

positive (+) terminal. Connect voltmeter negative

(black) lead to coil positive (+) terminal.

3.

Turn ignition switch "on" and observe voltmeter. A

reading of less than 1 volt should be obtained.

4.

Check circuit conditions by observing voltmeter while

flexing (moving) the connectors at the following

locations:

a.

Battery cables.

b.

Starter solenoid battery terminal.

c.

Dash panel (bulkhead) connector (where

used).

d.

Ammeter terminals.

e.

Ignition switch connections.

If fluctuation or an upswing of the voltmeter needle is

observed while flexing the connectors, a poor connection

exists and must be corrected.

Fig. 58 Primary Voltage Drop Test

1. Battery

7. Ammeter

2. Ignition Switch

8. Bulkhead Connector

3. Ignition Coil

9. To DTM

4. Distributor

10. To Alternator

5. Starter

11. Voltmeter

6. Solenoid

CGES-145-U Page 28

PRINTED IN UNITED STATES OF AMERICA

|