|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

10.

Check Dwell.

Connect dwell meter to engine. Operate engine and

observe dwell reading. If necessary, re-adjust trigger

wheel-to-sensor air gap to obtain specified dwell.

11.

Check Timing.

Connect timing light to engine. Operate engine at

idle speed (distributor vacuum hose disconnected)

and check timing. Adjust timing if necessary.

SECONDARY CIRUCIT INSPECTION

Secondary

(high

voltage)

system

components

(distributor cap, rotor, coil, high tension cables and spark

plugs) should be checked as possible sources of trouble

before condemning the electronic units.

Distributor Cap and Rotor

Inspect distributor cap and rotor for cracks, carbon

tracking, loose terminals, dirt and contamination. Clean or

replace as needed.

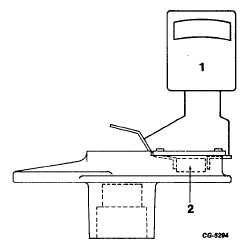

Check rotor blade and spring for tightness. Check fit

of rotor on distributor shaft. Check resistance type rotor with

ohmmeter. (Figure 56). If resistance exceeds 6000 ohms,

replace rotor.

Fig. 56 Rotor Resistance Test

1. Ohms X1000 Meter

2. Resistor

Coil

Inspect coil tower for cracks or carbon tracking.

Inspect primary terminals for corrosion and/or looseness.

Replace coil if any of these conditions are found.

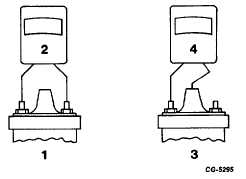

Test resistance of coil primary and secondary circuits

with an ohmmeter (See Figure 57).

COIL RESISTANCE TESTS

Fig. 57 Coil Resistance Tests

1. Primary Circuit

3. Secondary Circuit

2. Ohms X1

4. Ohms X1000

If coil resistance tests are made with coil mounted in

vehicle, coil must be electrically isolated from the vehicle's

electrical system by disconnecting primary leads from coil

terminals and removing secondary cable from coil tower.

Set ohmmeter in OHM x 1 position. Connect

ohmmeter between coil primary terminals. Reading should be

between 1.2 and 1.4 ohms at 21 degrees C (70 degrees F).

Set ohmmeter in OHM x 1000 position. Connect

ohmmeter between one coil primary terminal and the coil

tower terminal. Reading should be within 9,000 to 12,000

ohms at 21 degrees C (70 degrees F).

If coil fails either resistance test, replace it.

High Tension Cables

Inspect secondary (high tension) ignition cables for

deterioration, carbon tracking at terminal boots and high

voltage leakage, especially at cable support brackets.

Test resistance of cables with an ohmmeter.

Resistance should not exceed 30,000 ohms on cables up to

914 mm (36") long or 45,000 ohms on cables over 914 mm

(36") long.

Check sealing and insulating qualities, of distributor

cap, coil tower and spark plug boots. Replace if needed.

CGES-145-U Page 27

PRINTED IN UNITED STATES OF AMERICA

|