|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

C.

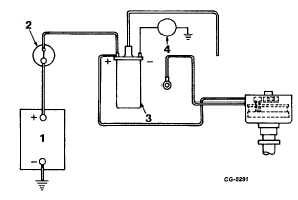

If voltage is 0 to 5 volts:

Disconnect voltmeter. Remove brown wire from coil

negative (-) terminal. Reconnect voltmeter between

coil negative (-) terminal and ground (Figure 53).

With ignition switch "on", observe voltmeter. If

voltage reading is still 0 to 5 volts, coil is faulty and

must be replaced.

If voltage increases to 12 - 13 volts, electronic control

unit in distributor is faulty, and must be replaced.

Reconnect brown wire to coil (negative (-) terminal).

Fig. 53 Testing With Brown Wire Removed

1. Battery

3. Ignition Coil

2. Ignition Switch

4. Voltmeter

7.

Test control unit operation.

Voltmeter should be connected between coil negative

(-) terminal and ground (Figure 53).

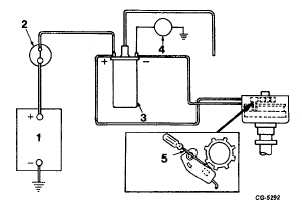

With ignition switch "on", place blade of screwdriver

against face of sensor (Figure 54) while observing

voltmeter. Voltage should increase to 12 - 13 volts.

Remove screwdriver blade. Voltage should drop to 5

- 8 volts.

If voltage switches up and down, proceed to step 8.

If voltage does not switch up and down when

screwdriver blade is placed against and then

removed from face of sensor, electronic control unit

in distributor is faulty and must be replaced.

8.

Test Coil Operation

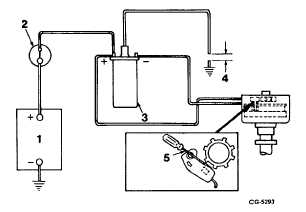

Re-establish the 13 mm (1/2 inch) gap between

extension adapter (connected to coil high tension

cable) and engine (Figure 55).

Fig. 54 Testing Electronic Control Unit

Operation

1. Battery

3. Ignition Coil

2. Ignition Switch

4. Voltmeter

5. Screwdriver

Fig. 55 Testing Coil Operation

1. Battery

3. Ignition Coil

2. Ignition Switch

4. 13 mm (1/2 in.) gap

5. Screwdriver

With ignition switch "on" observe for spark across

gap each time screwdriver blade is placed against

face of sensor.

If no spark occurs, coil is faulty and must be

replaced.

9.

Retest for Spark at Plug.

After

replacing

components,

disconnect

test

equipment. Reinstall shield, rotor and distributor cap

and reconnect coil high tension cable to distributor

cap.

Recheck for spark at spark plug (Step 2).

CGES-145-U Page 26

PRINTED IN UNITED STATES OF AMERICA

|