|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

end of tooth (Figure 43). Move sensor as

needed to obtain specified air gap (see

DISTRIBUTOR TEST SPECIFICATIONS).

Tighten sensor mounting screw and recheck air

gap.

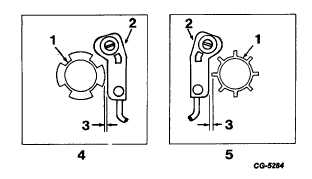

Fig. 43 Trigger Wheel-to-Sensor Air Gap

1. Trigger wheel

2. Sensor

3. Air gap

4. 4 cylinder engine

5. 8 cylinder engine

8.

Mount distributor in distributor test stand. (See

Distributor Operation Test).

9.

Operate distributor at 300 RPM (with 12-13 volts

primary input and observe dwell reading. Dwell

should be within specified limits.

a.

If dwell reading is within specified limits,

trigger wheel to-sensor gap is satisfactory.

b.

If dwell reading is not within specified limits,

loosen sensor mounting screw and adjust

trigger wheel-to-sensor air gap as required to

obtain specified dwell. Move sensor toward

trigger wheel to decrease dwell or away from

trigger wheel to increase dwell. Dwell is

affected approximately one-half (½ ) degree

per .025 mm (.001 in.) of sensor movement.

After correct dwell is obtained, tighten sensor

mounting screw.

10.

The mechanical advance mechanism is calibrated at

the factory and no further calibration is required.

11.

Connect test stand vacuum hose to vacuum advance

diaphragm and check operation of vacuum advance.

If advance does not fall within specified vacuum

readings, replace vacuum diaphragm and recheck

vacuum advance operation.

12.

If distributor operation is satisfactory, remove

distributor from test stand and install dielectric shield

(dust cover) and rotor.

CGES-145-U Page 21

PRINTED IN UNITED STATES OF AMERICA

|