|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

6.

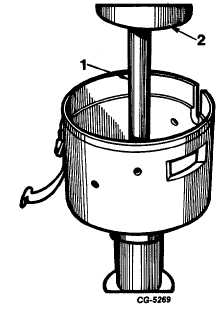

Place distributor housing on press bed. Insert knock-

out bar through upper bushing bore and allow to rest

on end of bushing remover installed in lower bushing.

Pressing against knock-out bar, press lower bushing

from distributor housing (Figure 28)

Fig. 28 Pressing Out Lower Bushing Using Knock-Out Bar

1. Knock-Out Bar

2. Press Ram

7.

On distributors without tachometer drive, wash

distributor housing in cleaning solvent to remove old

lubricant from upper bushing lubricant reservoirs

(Figure 35).

8.

On distributors with tachometer drive, remove cover

from tachometer drive cavity and wash distributor

housing in cleaning solvent to clean old lubricant

from cavity. (See Tachometer Drive Service)

Bushing Installation

1.

Lubricate outer diameter of new upper bushing with a

light coat of grease and start bushing into distributor

housing bore.

IMPORTANT

On distributors without tachometer drive, groove

in

outside

diameter

of

bushing

must

be

positioned at the top (Figure 29).

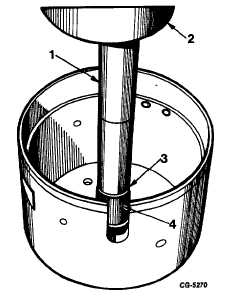

2.

Position distributor housing in press. Insert bushing

installer (SE-1955-7) into bushing (Figure 29).

Fig. 29 Installing Upper Bushing Using Bushing Installer SE-

1955-7.

1. Installer

3. Groove

2. Press Ram

4. Upper Bushing

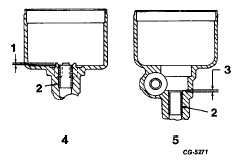

3.

Press upper bushing into housing to dimension

shown in Figure 30:

On distributors without tachometer drive, 2.4 mm

(3/32 inch) below top of bushing support ribs.

On distributors with tachometer drive, flush to 0.8

mm (1/32 inch) below surface of tachometer drive

counterbore.

Fig. 30 Upper Bushing Location Dimensions

1.

2.4mm (3/32 in.)

2.

Bushing

3.

Flush to 0.8mm (1/32 in.)

4.

Without Tach Drive

5.

With Tach Drive

CGES-145-U Page 14

PRINTED IN UNITED STATES OF AMERICA

|