|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

4.

Lubricate outer diameter of new lower bushing with a

light coat of grease and start bushing into distributor

housing bore.

5.

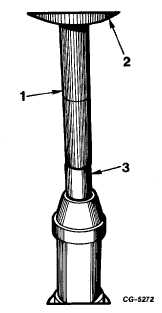

Position distributor housing in press. Insert bushing

installer (SE1955-7) into bushing (Figure 31).

Fig. 31 Installing Lower Bushing using Installer SE-1955-7.

1. Installer

3. Lower Bushing

2. Press Ram

6.

Press lower bushing into housing to dimension

shown in Figure 32.

On distributors for all engines except V-537, 2.4 mm (3/32

inch) below bottom end of distributor housing.

On distributors for V-537 engines, flush with surface of oil seal

counterbore.

Fig. 32 Lower Bushing Location Dimensions.

1. All distributors except for V-537 engine

2. Distributor for V-537 engine

3. Bushing

4. Bushing flush with housing.

5. 2.4 mm (3/32 in.)

After bushings have been installed, check fit of distributor

shaft in bushings. Size bushings if necessary to obtain .008 -

.038 mm (.0003 - .0015 inch) running clearance.

IMPORTANT

The oilite bushings should not be reamed.

Swelling and burrs may be removed with a

burnishing

tool.

For

distributors

without

tachometer drive, use burnisher tool SE-1955-2.

For distributors with tachometer drive, use

burnisher tool SE-2779.

7.

If shaft passes through upper bushing but binds in

lower bushing, burnish lower bushing. Burnish lower

bushing only. If shaft does not pass through or binds

in upper bushing, burnish upper bushing first and

repeat check for shaft fit. Then burnish lower

bushing, if needed.

To burnish bushings:

a.

Place flat end of burnisher in a vise. Coat

burnisher with SAE-20 engine oil.

b.

Burnish upper bushing by carefully placing

distributor housing on burnisher and rotating

the housing clockwise using light pressure

until tool passes through bushing (Figure 33).

c.

Burnish lower bushing per step "b" above.

CGES-145-U Page 15

PRINTED IN UNITED STATES OF AMERICA

|