|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

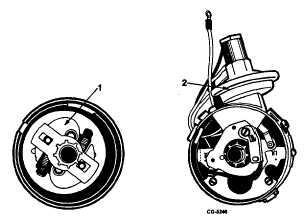

The vacuum advance system incorporates a vacuum

diaphragm unit which rotates the distributor sensor plate in

response to changes in carburetor throttle bore vacuum.

The two systems, mechanical and vacuum (Figure 5)

operate independently, yet work together to provide proper

spark advance.

Fig. 5 Spark Advance Systems

1.

Mechanical (Centrifugal) Advance Mechanism

2.

Vacuum Advance Diaphragm Unit

MAINTENANCE

To perform effectively, the ignition system must be

properly maintained. It is important that ignition system

maintenance operations be performed at the specified time or

mileage intervals.

For ignition system maintenance intervals, procedures

and specifications, refer to the appropriate "Emission Control

Systems and Service Operations" section of the Truck Service

Manual as listed below.

For vehicles built in 1978, see

CTS-2733

For vehicles built in 1979, see

CGES-135

For vehicles built in 1980, see

CGES-215

For vehicles built in 1981, see

CGES-300

DISTRIBUTOR SERVICE

DISTRIBUTOR REMOVAL

1.

Unfasten distributor cap retaining clips. Remove

distributor cap (with high tension cables) and position it

out of the way.

2.

Disconnect vacuum hose from distributor vacuum

advance unit, if equipped.

3.

Disconnect distributor wiring as follows:

a.

Disconnect distributor leads from positive and

negative terminals of. ignition coil.

b.

Disconnect deceleration throttle modulator lead

(white wire) at connector (where used).

4.

Disconnect tachometer drive cable, if equipped.

5.

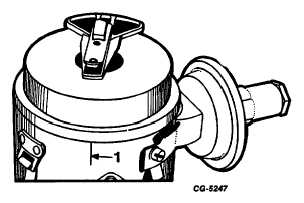

Scribe a mark on distributor housing in line with tip of

rotor (Figure 6) and note position of rotor and

distributor housing in relation to surrounding engine

parts as reference points for reinstalling distributor.

Fig. 6 Rotor Position Reference Mark

1.

Scribe Mark

6.

Remove distributor hold-down bolt and clamp.

7.

Carefully withdraw distributor from engine. Do not lose

gasket or "O" See Figure 7 for gasket or "O" ring

location on distributor.

CGES-145-U Page 5

PRINTED IN UNITED STATES OF AMERICA

|