|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

Trigger wheels of distributors for four-cylinder engines

have four (4) teeth. Distributors for eight-cylinder engines

have eight (8) teeth on the trigger wheel.

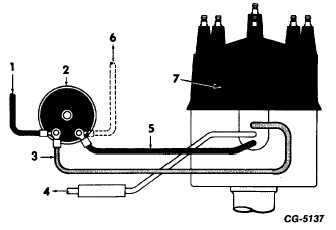

Distributor primary wiring consists. of two leads

connected to the ignition coil primary terminals. The red wire

from the distributor connects to the coil positive (+) terminal.

The brown wire from the distributor connects to the coil

negative (-) terminal. (See Figure 4). A third (white) wire

from the distributor connects to the deceleration throttle

modulator (DTM), where used. Because primary (low voltage)

current is regulated within the electronic control unit, a ballast

resistor or resistance wire is not required in the primary

circuit.

Fig. 4 Distributor Primary Wiring

1.

From ignition switch

2.

Ignition coil

3.

Red wire

4.

To decelerate throttle modulator (where used)

5.

Brown wire

6.

To governor control unit (where used)

7.

Distributor

The secondary (high voltage) components are: coil

tower, distributor cap, rotor, high tension cables and spark

plugs. The new distributor cap featuring superior physical and

dielectric strength incorporates male (spark plug type)

terminals. A resistor type rotor, interference suppression type

spark plugs are used to meet radio frequency interference

standards.

All distributors have a mechanical (centrifugal) spark

advance system. Most distributors also have a vacuum

operated spark advance system. The advance systems

automatically provide the optimum spark timing for various

engine speed and load conditions.

OPERATION

When the ignition key is turned on, an oscillating signal

is set up in the sensor circuit. This creates a field around the

sensor. When a trigger wheel tooth enters the sensor's field,

it squelches or reduces the strength of the oscillating signal.

This weakened sensor signal is detected by what is called a

demodulator circuit in the electronic circuit board. The

demodulator circuit controls a transistor to turn off the current

in the primary circuit of the coil. When the transistor is turned

"off", it opens ("breaks") the coil primary circuit. As in a

conventional system, opening the coil primary circuit induces

high voltage in the coil secondary circuit which is conducted

from the coil to the distributor cap and travels through the

rotor and the secondary cables to the spark plugs. When the

trigger wheel tooth leaves the sensor's field, the transistor is

turned "on" to close ("make") the coil primary circuit.

Dwell angle is determined by the angle between

adjacent teeth of the trigger wheel and by the air gap between

the ends of the trigger wheel teeth and the sensor. Since

there are no wearing surfaces connected with the trigger

wheel and sensor, dwell remains constant and should not

require adjustment for the service life of the distributor.

The mechanical (centrifugal) advance system is built

internally into the distributor and consists of two flyweights

which pivot on long life, low friction bearings and are

controlled by calibrated springs which tend to hold the weights

in the no-advance position. The flyweights respond to

changes in _ engine (distributor shaft) speed and rotate

the trigger wheel to advance the spark as engine speed

increases and retard the spark as engine speed decreases.

CGES-145-U Page 4

PRINTED IN UNITED STATES OF AMERICA

|