|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

significantly from these figures. Before condemning

a rotor for an open coil, check the solder joints at the

slip ring leads, as a poor connection at either of

these leads will test the same as an open coil. If the

proper resistance is not obtained after resoldering

these connections, discard the rotor.

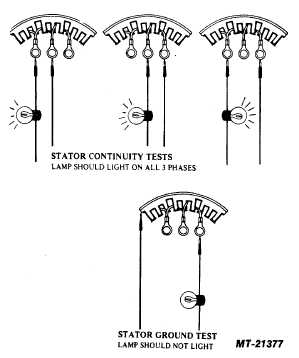

STATOR TEST

Due to the extremely low resistance of the stator

windings it is difficult to measure their resistance with a

conventional ohmmeter. The stator should therefore be tested

for grounds and continuity between phases with a test light. A

12 volt test light is preferred.

Do not attempt to check stators in this manner while

they are still connected to the heat sinks. Remove the stator

from the alternator before testing (see Fig. 22 for stator test).

Discard any stators which appear overheated and have

charred insulation, regardless of how they test.

Several stators are available which can be used as

service replacements on these alternators. The part numbers

of these stators will be listed in the appropriate parts list.

SLIP RING REPLACEMENT

The slip ring assembly used in these alternators is of

extremely sturdy construction and will seldom require

replacement. If it should become damaged in some way,

such as dropping the rotor, it may be replaced in the following

manner.

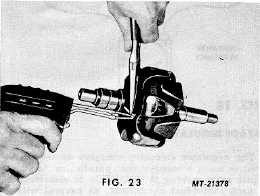

1. Unsolder the slip ring leads and lift them clear of the

eyelets which serve to retain them to the rotor coil leads.

Do not lose or damage the eyelets (see Fig. 23).

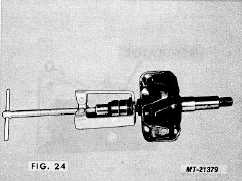

2. With a suitable puller, the slip ring assembly may now be

pulled from the shaft (see Fig. 24).

3. Clean the rotor shaft and apply a small amount of Loctite

to the shaft on the section normally occupied by the slip

ring assembly.

4. Position the new slip ring assembly on the shaft so that the

two leads are aligned with the two rotor coil eyelets on the

rotor, and carefully press the slip ring assembly onto the

shaft.

FIG. 22

CTS-2743T Page 10

|