|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

Its value is .5 MFD, and 200 working volts D.C.

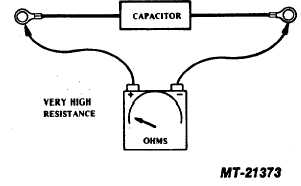

In the absence of a capacitor tester, the unit may be checked

for shorts by means of an ohmmeter connected across the

terminals. A low resistance reading indicates a shorted or

leaking capacitor which should be replaced (see Fig. 18).

VOLTAGE REGULATOR TEST

The regulator circuitry contains devices connected in such a

manner that parallel or "sneak" circuits exist making it

impossible to electrically test each individual component, as

several will be in the circuit at the same time. For this reason,

point to point resistance checks with an ohmmeter may be

inconclusive or misleading. The regulator can be most

accurately tested by installing it in an alternator known to be

serviceable.

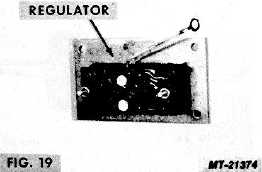

The voltage regulator assembly consists of a number of

individual components such as capacitors, resistors, diodes

and transistors, mounted upon and electrically connected by a

printed circuit panel. Because these components are

permanently fastened to the panel, their replacement is not

recommended. When it has been

determined that a voltage regulator is unserviceable, it should

be discarded and a new assembly installed in its place (see

Fig. 19).

ROTOR TEST

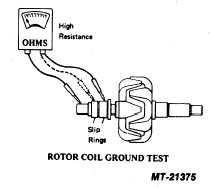

The rotor should be checked for grounds and proper coil

resistance with an ohmmeter.

1. With the ohmmeter connected between the rotor shaft and

either slip ring, no reading (infinity) should be obtained. If an

ohmmeter reading other than infinity is obtained, the rotor coil

is grounded and the rotor must be replaced (see Fig. 20).

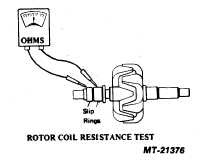

2. Check rotor coil resistance by connecting the ohmmeter

across the two slip rings (see Fig. 21). The resistance of the

rotor should be within the following limits:

2310JB

4.9-5.5 Ohms

2510JB

2.3-2.7 Ohms

2610JB

2.3-2.7 Ohms

2810JB

1.9-2.3 Ohms

Discard

rotors

whose

resistance

values

differ

PRINTED IN UNITED STATES OF AMERICA

FIG. 18

FIG. 20

FIG. 21

CTS-2743T Page 9

|