|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

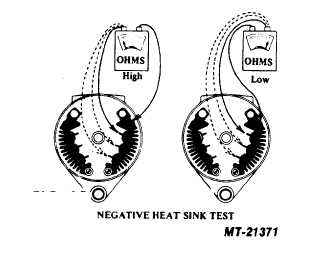

Negative Heat Sink Tests:

1. Connect the negative test lead to the negative heat sink

and touch the positive test lead to each diode terminal. If a

low resistance reading is obtained or if the test lamp lights,

the diode is shorted (see Fig. 15).

2. Reverse the test leads so that the positive test lead is

connected to the negative heat sink. Touch the negative lead

to each of the three diode terminals. A low resistance reading

should be obtained, and if a test light is being used, the lamp

should light. If high resistance is indicated or the lamp does

not light, the diode is open (see Fig. 16).

If a shorted or open diode is detected in the preceding tests,

the entire heat sink assembly should be replaced.

Heat sinks supplied as service replacements may differ

slightly in thickness or general appearance from the original

parts. This will

in no way impair their interchangeability or reliability. To

obtain

the

maximum

serviceability,

several

different

assemblies may be used as replacements. These will be

listed in the appropriate parts list.

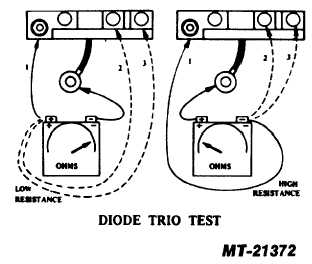

DIODE TRIO TESTS

The diode trio may be tested with the same equipment which

was used to check the diodes in the heat sink assemblies.

1. Connect the negative lead of the tester to the output lead

of the diode trio, and touch the positive tester lead to each of

the three copper terminal pads (see Fig. 17). A low

resistance should be indicated, and if a test lamp is being

used, it should light.

2. Connect the positive terminal of the tester to the output

lead of the diode trio and touch the negative lead to each of

the three copper terminal pads. A high resistance should be

indicated and if a test lamp is being used, it should not light.

Discard any diode trio which does not pass all of these tests.

CAPACITOR TEST

The capacitor connected across the heat sinks may be tested

on a capacitor tester if available.

PRINTED IN UNITED STATES OF AMERICA

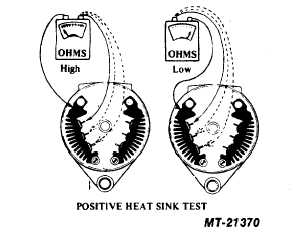

FIG. 13

FIG. 14

FIG. 15

FIG. 16

FIG. 17

CTS-2743T Page 8

|