|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

The voltage regulator used in these alternators is a solid

state device and for this reason will normally have an extremely

long life. It can, however, be, damaged by mechanical or

electrical abuse.

If the system polarity is inadvertently reversed by

installing a battery backwards, boosting or jump starting with

the jumper connected backwards, or reversing the positive and

negative alternator output leads when changing an alternator,

the voltage regulator will be damaged. Although the polarity

reversal may only be momentary and may not damage the

alternator diodes, the regulator will still be damaged.

ADJUSTMENT

Prior

to

adjusting

alternator

voltage,

the

wiring,

connections and belt tension should be checked and repaired as

needed. The batteries should be fully charged and the engine

should be running at a fast idle. Turn off all vehicle loads such

as lights, radios, heaters. air conditioners, etc. when checking

or adjusting voltage. An accurate voltmeter should be

connected across the batteries to determine the charging

voltage. Do not rely on dash mounted vehicle instruments.

These are excellent indicators but usually lack the extreme

accuracy required for regulator adjustment. Remove nylon

screw (plug) from the regulator (see Fig. 1), and with a small

screwdriver carefully turn the adjusting screw clockwise to raise

or counter-clockwise to lower the voltage. The ideal voltage

setting will be a value which maintains a fully charged battery

without resulting ill all excessive usage of battery water.

When turning the voltage adjustment screw, do not

attempt to force it past its stop as damage will result. Be sure

to replace the screw (plug) in the regulator adjustment hole to

prevent the entrance of water and dirt.

DISASSEMBLY

1.

Remove pulley nut, pulley, fan, key and spacer. Use a

suitable puller to avoid damage to the shaft and

threads.

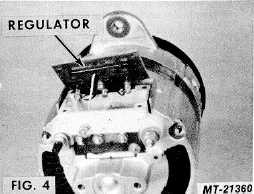

2.

Remove four screws and carefully lift regulator free of

housing. Remove red and black leads from regulator,

noting their position to facilitate reassembly (see Fig.

4).

3.

Remove lead from diode trio to terminal on regulator

housing. Loosen inner nut, which will allow blue

regulator lead to be withdrawn from under head of

terminal screw. Remove regulator (see Fig. 4).

4.

Lift brush and spring assemblies out of housing (see

Fig. 4).

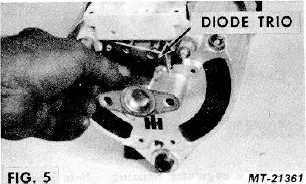

5.

Remove three nuts and lift diode trio off of A/C

terminal studs (see Fig. 5).

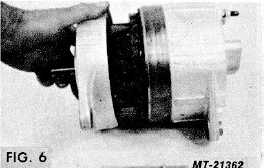

6.

Remove three self locking nuts and through bolts.

7.

Remove rotor and drive end housing assembly from

stator and slip ring end housing assembly. If drive end

housing binds on stator, loosen by tapping gently on

mounting ear with fibre hammer. Be sure that drive

end housing separates from stator and that stator

remains attached to slip ring end housing to avoid

damage to stator leads (see Fig. 6).

CTS-2743T Page 5

PRINTED IN UNITED STATES OF AMERICA

|