|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

TROUBLE SHOOTING

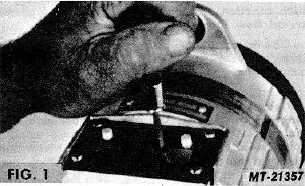

Before performing trouble shooting procedures on the

vehicle, be absolutely certain that wiring is not defective and

belts are not slipping, as these problems are common.

To determine if the problem lies in the regulator or the

alternator, connect an accurate voltmeter across the battery

with the engine stopped, and note the reading. The engine

should now be started. If the voltmeter reading rises

excessively, the charging system may be defective or may

require adjustment. Remove the nylon screw from the regulator

and with the engine at approximately 1000 RPM, attempt to

bring the voltage to its proper value (13.8-14.2 V approximately)

by turning the adjusting screw back and forth with a small

screwdriver (see Fig. 1).

If the voltage is excessively high and cannot be lowered

by means of the adjustment, the regulator is probably defective

and should be replaced. If the output voltage cannot be raised,

either the alternator, regulator or diode trio may be at fault. To

determine if the fault is in the regulator or in the alternator,

perform the following test.

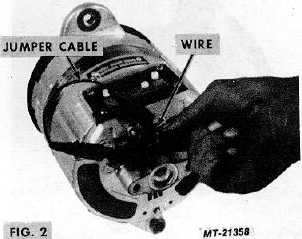

Connect one end of a short jumper lead to the negative

alternator output terminal and connect the other end of the

jumper to a short stiff piece of wire at least 38 mm (1 1/2") long.

A piece of paper clip wire will be suitable. Insert this wire into

the small hole in the end of the brush holder so that it firmly

contacts the outer brush terminal. (see Fig. 2).

If the voltmeter reading now rises with the engine at a

fast idle, the alternator is OK and the fault is in the regulator or

diode trio. Remove the diode trio and test (see "COMPONENT

TESTING"). If the diode trio tests OK, the regulator should be

replaced.

If the voltage fails to rise when performing this test,

remove the regulator and carefully inspect it for a printed circuit

track which has burned open. If this condition is found, replace

the regulator. Check the brush spring caps and their contact

screws for dirt or corrosion and clean if necessary. If the

alternator does not operate after performing either or both of

these operations, the alternator should be removed for repair or

replacement.

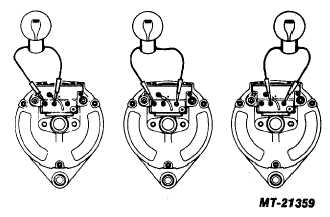

FIG. 3

The alternator may also be checked for output across

each phase by using a test light as shown in Fig. 3. The test

light should be constructed from a two filament sealed beam

unit connected in such a manner that the filaments are in

parallel. Such a light will act as a load a as well as an indicator,

and should light with equal brilliancy on each phase. If the

lamp is noticeably dimmer on one or two phases, a defective

diode trio or power diode is indicated. If the diode trio tests OK,

then the alternator must be removed and dismantled for further

tests.

CTS-2743T Page 4

PRINTED IN UNITED STATES OF AMERICA

|