|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

DESCRIPTION

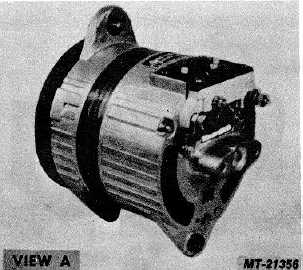

The IH heavy duty alternators (View A) are 14 volt self

load limiting alternators which feature a fully adjustable, built-in

solid state voltage regulator.

The alternators incorporate a 22.2 mm (7/8") straight

shaft, a large ball bearing at the drive end and a roller bearing

at the slip ring end. The alternators have a two leg swivel

mounting, one leg of which is equipped with a slideable

bushing. The rotor shaft may be rotated in either direction.

Six silicone diodes mounted in heat sinks convert

alternating current from the delta wound stator into direct

current. A capacitor connected between the heat sinks assists

in suppressing transient voltage spikes which could possibly

injure the diodes.

The brushes and voltage regulator are located in a

waterproof housing and may be removed for replacement or

inspection without dismantling the entire machine. An external

relay terminal is also provided for operation of chargelight

relays or other accessories which might require power from

such a source.

The alternators have ungrounded output terminals so

that they may be used on either positive or negative ground

systems. Aside from connecting the proper vehicle wires to the

correct output terminals, no other wiring is required on the

alternator, eliminating field relays or ignition switch connections.

OPERATION

Current is produced by rotating a magnet called a rotor

inside a stationary winding called a stator.

The rotor is electrically magnetized by a small current

flowing through it via brushes riding on smooth slip rings.

Alternating current is produced as the magnet poles of

the rotor pass through the coil windings of the stator. For

increased capacity, there are twelve (12) magnetic poles

incorporated into the rotor and three (3) separate windings in

the stator. Since alternating current is produced as the rotor

passes the coil windings of the stator, increased engine speed

produces more current.

The battery stores only direct current and cannot use

alternating current. For this reason, rectifier assemblies are

used to convert alternating current produced in the stator to

direct current. Rectifiers consist of silicon diodes which function

as electrical switches and permit current flow in only one

direction.

The rectifier diodes are mounted in aluminum castings,

called heat sinks, which are finned to dissipate heat.

A built-in solid state voltage regulator controls alternator

output and the battery's state of charge. The diode trio, so

called because it consists of three (3) diodes, converts a small

amount of alternator current from the stator into direct current

which is used as a signal to turn on the regulator.

The regulator senses when the battery has received

sufficient charge and then reduces the "field" (magnetizing)

current flow to the rotor. Reducing the field current flow, in turn,

reduces alternator output.

When headlights and/or accessories place a load on the

battery, the regulator increases the field current flow to the

rotor, thereby increasing alternator output.

PREVENTIVE MAINTENANCE

Mounting hardware including brackets and drive belts

must be periodically inspected and adjustments or repairs

performed as required. It is important that mounting bolts and

nuts be kept securely tightened to maintain belt alignment and

prevent vibration damage which will occur if mounting bolts

work loose.

Vehicle wiring must be inspected at periodic intervals for

loose or corroded connections and repairs made as needed.

CTS-2743T Page 3

PRINTED IN UNITED STATES OF AMERICA

|