|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BRAKES-HYDRAULIC

Excessive variation can cause pedal vibration or

fight, front end vibrations and possible "grab" during the

braking action--a condition comparable to an out-of-round

brake drum.

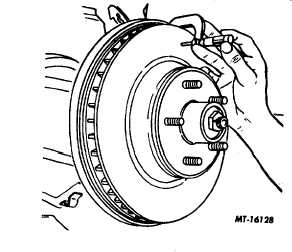

To make the thickness variation or parallelism check

on the rotor at the same time the runout is being checked, use

a micrometer to check the variation in thickness of the rotor at

four equal points around the rotor (Fig. 18).

Fig. 18 Checking Rotor with Micrometer

If the thickness varies more than .0127 mm (.0005

in.) refacing of the rotor will be required; or replace it if the

rotor will not true up before minimum allowable thickness is

obtained.

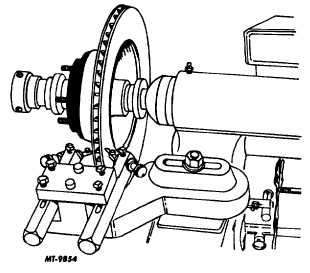

REMACHINING ROTORS

The rotors can be remachined to provide a new,

smooth braking surface (Fig. 19). If the rotor will not true up

before minimum allowable thickness (see Specifications) is

obtained, it must be replaced.

Fig. 19 Correct Method of Refacing Rotor

IMPORTANT

Rotors

are

identified

by

the

minimum

allowable thickness they can be used. Any

rotor thinner than the minimum dimension

must not be used.

Removal of too much metal would cause overheating

and, more important, a thin rotor could permit the seals in the

cylinder to "uncover".

To uncover a seal in the cylinder would result in loss

of hydraulic brake fluid. An uncovered seal would not be

apparent at first, but as the pads wear, more travel of the

cylinder would be required; and since the rotor would be too

thin, the seals could leak.

ROTOR REMACHINING SPECIFICATIONS

Brake Group

Code No

Rotor Original Thickness (New)

Minimum Allowable Remachining

Thickness

Minimum Use- able Thickness

in.

mm .

in

mm.

in

mm

04135

1.240

31.50

1.195

30.353

1.180

29.97

04138

1.180

29.97

1.135

28.429

1.120

28.45

04139

1.180

29.97

1.135

28.429

1.120

28.45

04140

1.180

29.97

1.135

28.429

1.120

28.45

CTS-2779 Page 8

PRINTED IN UNITED STATES OF AMERICA

|