|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BRAKES-HYDRAULIC

and drum surface. Grind new lining approximately 1.78 mm

(.070 in.) less than the inside diameter of brake drum. Make

certain that the brake is fully released before grinding.

DISC BRAKES

INSPECTION OF ROTORS

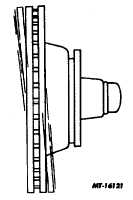

Inspect rotors for lateral runout, parallelism, (Fig.

14), cracks or burnt marks.

The disc brakes may have a slight amount of runout

or wobble due to tolerances which are required in machining

the large flat surfaces of the rotor.

Fig. 14 Rotor Lateral Runout

Lateral runout is the movement of the rotor from side to side

as it rotates. Excessive runout causes the rotor faces to

knock back the disc pads and can result in chatter, excessive

pedal travel, pumping or fighting pedal and vibration during

the braking action. This condition can be due to a warped

rotor, loose wheel bearing and, especially if symptoms

develop immediately after sharp turns, deflection in steering

or suspension.

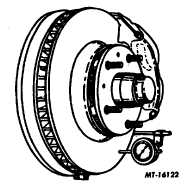

Runout is measured by a dial indicator SE1848 (Fig. 15) set

against the rotor surface approximately 25.4 mm (1 in.) from

outer edge of rotor. Runout should not exceed .105 mm (.

004 in.) Excessive runout will kick back the shoes, cause an

increase in pedal travel needed to apply the brakes, and pedal

vibration will be felt during applications. It also contributes to

"grab", "pull" and noise problems.

Do not overlook wheel bearing adjustment. Wheel bearings

which are loose can cause excessive runout indication.

If rotor runout exceeds .105 mm (.004 in.) either refacing or

new rotor assembly will be required.

Fig. 15 Dial Indicator Installation

Fig. 16 Rotor Not Satisfactory for Service

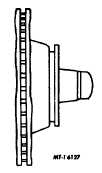

Rotors

should

be

inspected

for

parallelism.

Parallelism refers to the amount of variation in thickness' of

the rotor (Fig. 17).

Fig. 17 Rotor Parallelism or Variation In Thickness

CTS-2779 Page 7

PRINTED IN UNITED STATES OF AMERICA

|