|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BRAKES-HYDRAULIC

The terms micrometres, micro-inch or surface finish

or smoothness are different from runout and parallelism.

These terms refer to degree of how smooth the flat surface is.

However, if good, sharp tools and proper cutting feed and

speed are used when remachining the rotor, you should be

within

the

.381-2.032

micrometres

(15-80

micro-inch)

tolerances.

INSPECTION OF PADS

The disc brake pads or shoes can be inspected for

wear on the vehicle. It is normal for the inboard lining to show

more wear than the out board lining. Always install new pads

assemblies in complete axle sets at both wheels on an axle.

Since lining on disc brakes will be bonded (code

04135) and riveted (codes 04138, 04139 & 04140) the

useable thicknesses will be different.

Pads with bonded lining (code 04135) must be

replaced when lining is worn to .7937 mm (1/32 in.) or less.

Pads with riveted lining (codes 04138, 04139 &

04140) must be replaced when lining is worn to 3.1750-

4.7625 mm (1/8 to 3/16 in.) or less.

It is suggested that the pads be replaced whenever

they are removed for an inspection or for any other service

and they are found to be worn to 2.778 mm (7/64 in.) from

shoe surface with bonded material, or from rivet heads to

brake lining surface.

DRUM REPLACEMENT

Different assembly methods are used to hold brake

drums in their piloted position on hub while wheels are

dismounted.

LIGHT DUTY VEHICLES

Drums which are mounted against wheel flange on

light duty vehicles are secured to studs either with speed nut

fasteners or by swagging the piloting shoulder of stud to

drum. To replace an original drum proceed as follows:

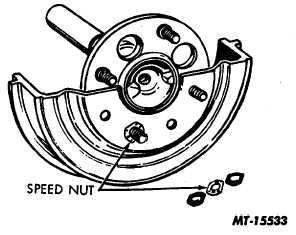

Where threaded fasteners (Fig. 20) are used simply

unthread speed nuts and lift drum from flange.

Fig. 20 Threaded Fastener Type Drum Mounting

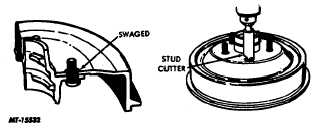

If swaged stud mounting (Fig. 21) is used, chuck a

stud cutter in an electric drill, align cutter over each stud and

cut away the swaged material. Separate drum from hub and

discard drum.

Fig. 21 Swaged Stud Type Drum Mounting

MEDIUM AND HEAVY DUTY VEHICLES

Drum replacement on medium and heavy duty

vehicles requires the removal of nuts from bolts securing hub

and drum together. The hub and drum can then be

separated.

MOUNTING NEW DRUM TO HUB

Clean exposed hub or axle mounting flange with wire

brush or coarse file. Use straight edge across surface of

flange to make sure it is not bent. Remove excess paint from

edge of drum hub hole and wash rust preventive sealer from

drum with solvent.

CTS-2779 Page 9

PRINTED IN UNITED STATES OF AMERICA

|