|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

3.

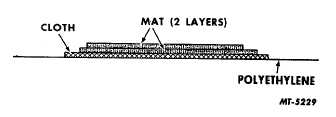

On a piece of polyethylene place a piece of cloth cut

larger than hole being repaired. Saturate with resin

mixture. Obtain a layer of mat cut larger than the hole

being repaired and position it on the cloth. Saturate

mat also with the resin mixture.

4.

Coat the inner surface of area being repaired with the

resin mixture. When tacky, apply the patch prepared in

item 3. Using the polyethylene sheet press out air

pockets and allow patch to cure.

5.

On a piece of polyethylene, place another piece of cloth

larger than hole being repaired. Saturate with resin

mixture. Apply two layers of mat (Fig. 4), saturating

both with the resin mixture. Coat the outer surface of

area being repaired with the resin mixture. When

tacky, position the entire patch on the prepared surface

and press into position. Allow the patch to cure.

Fig. 4

6.

After the inner and outer patches have cured, peel off

the polyethylene and smooth the outer surface. Any of

the polyethylene material left on patch will be removed

when sanded.

7.

In the resulting low spots, apply plastic putty. Then

over the putty place another sheet of polyethylene and

squeeze well to remove all air. When putty has cured,

remove polyethylene and sand down to a feather edge.

Crack or Split:

1.

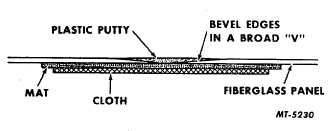

Remove loose material and grind to a broad "V" (Fig.

5). Clean inner panel also.

2.

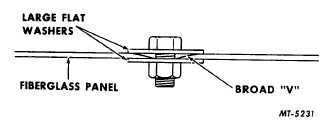

Align parts. A nut and bolt with large flat washers may

be used to draw parts together. See Fig. 6.

3.

Cut one or two pieces of mat and apply

to inner surface with resin mixture. (On cracks where

excessive stresses may occur, apply two pieces of

mat). Apply a piece of cloth with the resin mixture to

the inner surface also. Extend patches beyond break

about 2". Press the patches firmly into place and allow

to cure. NOTE: It is a recommended procedure to

leave the washer and nut (if used) in the patch if the

mat and cloth were applied over them.

Fig. 5

4.

Mix a fresh supply of plastic putty and apply over the

outside surface filling the large "V" like valley (Fig. 5).

Before the plastic putty cures, remove the bolt and

washer (if used) from the outside and fill the hole with

putty and allow to cure.

Fig. 6

5.

After the putty has cured, sand down to the exposed

surface.

Small Scratches or Chipped Area:

(No damage to basic fiberglass structure)

Remove paint from area being repaired and fill

damaged area with a plastic putty mixture. After area

has cured sand smooth.

FIBERGLASS SERVICE FENDER INSTALLATION (D-400

Series Illustrated)

1.

Remove and place hood assembly on level surface or

support frame. See Fig. 7. Hood should be blocked so

it is horizontal as nearly as possible. See Fig. 8.

CTS-2408 Page 4

PRINTED IN UNITED STATES O F AMERICA

|