|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

Scissors

Polyethylene (Plastic Container Bag Material) or

Cellophane Sheets Assorted Bolts, Nuts and Rivets.

SAFETY PRECAUTIONS

Observe The Following When Making Repairs With

Fiberglass

1.

Avoid spilling the resin or hardener on skin or clothing.

If this occurs, remove with paint thinner or denatured

alcohol. Then wash with soap and water. If the mixture

contacts

the

eyes,

flush

thoroughly

with

water

immediately. Continue flushing for at least 15 minutes

and contact physician as soon as possible.

2.

In some cases, some individuals may have skin

sensitivity to the use of these materials. Because of

this, protective creams can be applied to the hands to

guard against irritation.

3.

When protective creams are not available, rubber

gloves may be used to protect the hands. The gloves

can be removed quickly leaving the hands clean for

other work.

4.

When working with fiberglass always work in a well

ventilated area. DO NOT SMOKE OR EXPOSE

FLAME WHERE KITS ARE BEING USED OR

STORED. If possible, obtain a kit of material large

enough to accommodate only one or two jobs to avoid

storing any quantity of this material. Resin liquid must

be kept in a metal container or cabinet when not being

used.

5.

Repairs

must

be

ground

or

sanded

to

match

surrounding contours. When grinding or sanding, it is

advisable to use an approved type respirator during the

operation. Suitable respirators are available under

equipment number SE-1798 and SE-1799. The ground

dust or particles of resin or fiberglass must not be

inhaled, otherwise irritation may occur.

REPAIRING FIBERGLASS

Small Holes (Under 3" Diameter):

1.

Remove damaged material such as loose fiberglass

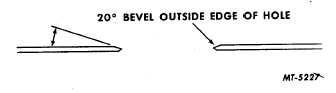

and bevel the edges (approximately 200). See Fig. 2.

Fig. 2

2.

Remove paint from outside surface with sandpaper.

Clean inner surface (if accessible).

3.

Cut a piece of cloth and a piece of mat so that the

patches will extend past the edges of the hole about 2".

4. Coat both inner and outer surfaces with resin mixture and

saturate both the mat and cloth.

5.

When tacky, apply the mat on the inner surface and the

cloth to the outer surface. Press the two patches

together using polyethylene. A saucer-like depression

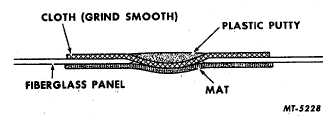

should be made. See Fig. 3.

Fig. 3

6.

Allow the material to cure. This is a chemical action

and not a drying action. A hard surface indicates a hard

interior. To hasten curing action heat lamps may be

used about 18" from work. Then smooth the outside

surface. Additional coats of resin mixture may be

added if necessary.

7.

Apply plastic putty to fill the low spots, allow time for

the putty to cure, then smooth the outside surface.

Large Holes (Over 3" Diameter):

1.

Remove damaged material such as loose fiberglass

and bevel the edges (approximately 200). See Fig. 2.

2.

Remove paint from the outside surface with sandpaper.

Clean the inner surface also if it is accessible.

CTS-2408 Page 3

PRINTED IN UNITED STATES OF AM ERICA

|