|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

GENERAL

The information contained in this manual section has

been prepared to provide service personnel with a ready

reference to step-by-step procedures for the repair or

replacement of fiberglass components.

Instructions for making fiberglass repairs to sheet metal

are also covered in this section.

A fiberglass reinforced plastic repair kit (Fig. 1) has been

made available which contains the material needed to repair

either fiberglass or sheet metal components. This kit may be

obtained through regular Service Part channels.

The mixing directions for the resin mixture and plastic

putty are found on the cans.

CAUTION

Do not put mixed material back into cans.

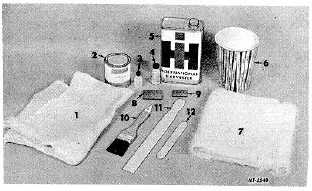

Fig. 1. Fiberglass Repair Kit.

Legend for Fig. 1

Key

Description

1

CLOTH

2

PLASTIC FILLER

3

PLASTIC ACTIVATOR

4

RESIN ACTIVATOR

5

RESIN

6

MIXING CUP (3)

7

MAT

8

SQUEEGEE (1-1/2" x 2")

9

SQUEEGEE (1-1/2" x 1")

10

PAINT BRUSH

11

STIRRING STICK

12

STIRRING STICK

DESCRIPTION

Fiberglass is manufactured from filaments of pure glass

spun into yarn then either woven into a fabric (cloth) or a

loosely bound mat. The cloth or mat is then saturated with a

resin. When the resin cures (hardens) it acts as a binder to

hold the fiberglass together, thus forming a solid panel.

Fiberglass components, such as the hood with fenders

assembly, are formed from laminated sheets of fiberglass

mats held together with a synthetic resin. When the liquid

resin mix cures (hardens) it binds the filaments of glass in the

fiberglass mat creates a solid panel. The glass fiber provides

the strength in the panel while the resin bonds the glass fibers

together and supplies only a limited additional amount of

strength. Therefore when repairing a section, be sure to cover

more than just the hole where the damaged material has been

removed. Always overlap the undamaged portion with

fiberglass patches, so that a more continuous sheet of

reinforced fiberglass results.

Since the material hardens by a chemical action, a hard

surface indicates a hard interior, ready for finishing. The

mixture becomes hot before reaching setting temperature and

then it begins to harden. It reaches full hardness after 48

hours. It can however be sanded and finished before then.

To hasten the curing action or if the working temperature

is below 60° F, hold a heat lamp approximately 18" from work.

NOTE

250° F to 275° F is the high limit for the

material and to go higher might distort the

fiberglass form you are patching. Therefore,

keep a close control over the external heat

supply. Cooler temperature increases the

working time and hardening time.

The paint refinishing method is the same as that

recommended for metal parts with the exception that the

temperature must be kept below 250° F, which means the air

dry process is the most practical method. Either enamels or

lacquers may be used to paint the fiberglass.

TOOLS AND EQUIPMENT NEEDED

Tools and equipment necessary to make repairs on

fiberglass are as follows:

IH Repair Kit (Fig. 1)

Putty Knife

Electrical Drill and Bits

Electrical Grinder or Sander

Respirator

"C" Clamps

Hacksaw Blades and Holder

Files

Acetone or Lacquer Thinner

CTS-2408 Page 2

PRINTED IN UNITED STATES OF AMERICA

|