|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

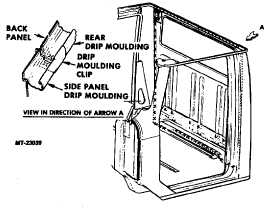

Fig. 50. Securing Drip Moulding Clip

4.

Obtain drip moulding clip and position clip so as to

close joint between old drip moulding on back of cab

and drip moulding on new side panel (Fig. 50).

Secure with one plug weld at each side of joint.

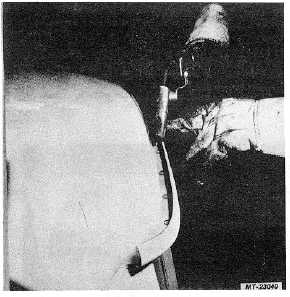

5.

Clamp outer roof panel to drip moulding of new side

panel assembly and plug weld roof panel to moulding

(Fig. 51).

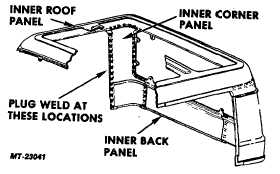

6.

Plug weld through holes drilled for removing to

replace inner corner panel to inside of cab (Fig. 52).

If new inner corner panel is used, plug weld holes

must be drilled into new panel before welding.

Fig. 51. Fastening Roof Panel To New Side Panel

Fig. 52. Installing Inner Corner Panel (Right Side - 80" Wide

Cab Shown)

7.

Grind, sand or wire brush away any excess weld or

weld ash from all newly welded areas.

8.

Obtain body sealant (Plastisol Type 1 or equivalent)

and apply to the following locations:

a.

Roof panel to drip moulding seam.

b.

Side panel to back panel joint at rear of cab.

c.

Dash filler panel to dash panel joint at front of

cowl.

d.

Drilled out holes on upper side of sill side inner

panel to rocker panel seam (under cab).

9.

Apply primer paint to affected areas to assure good

protection from rust. Finish paint as required.

OTHER PANEL REPAIRS

Since each cab panel component contributes to the

overall strength of the cab, proper welding, sealing and rust-

proofing practices must be observed for any other panel

replacement. Under-cab components especially should be

rust-proofed whenever cab repair operations are performed.

When rust-proofing cab components, use a good quality

air-dry zinc rich primer. Combination type primer-surfacer

paints are not recommended. Finish paint as required.

CTS-2714R Page 28

PRINTED IN UNITED STATES OF AMERICA

|