|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

BODIES AND CABS

INSPECT CAB STRUCTURE FOR DAMAGE

With side panel removed, inspect remainder of cab for

damage. Look especially for and repair:

1.

Damage to cab sill welds.

2.

Loosening of floor panels.

3.

Underbody bent out of alignment. (This step can

vary with each job. Keep in mind you are trying to

return cab to its original condition.)

Reweld any cracked or missing welds. The sill side inner

panel on the cab underbody must be straight and flat.

ALIGN NEW SIDE PANEL TO CAB

1.

Position and clamp new side panel assembly to side

of cab.

2.

Raise roof outer panel sufficiently to insert windshield

pillar top corner between inner and outer roof panels.

3.

Apply heat expanding type sealer (Plastisol or

equivalent) to this seam.

4.

Align panels to establish windshield opening and

install "C" clamps to secure.

5.

Align remaining joints at dash panel, cowl, roof panel

and back panel using "C" clamps to hold new side

panel in place.

WELDING SIDE PANEL TO CAB

1.

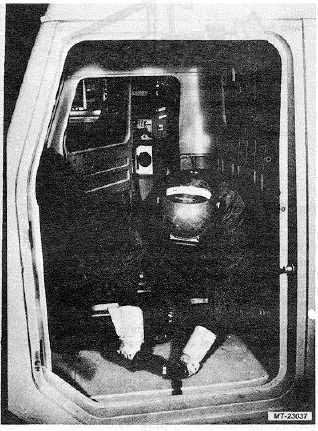

Using MIG welder inside cab (Fig. 48), plug weld

around door opening through holes drilled out of

original cab panels during side panel removal.

CAUTION

Adjust welder so as not to damage or burn

sheet metal when performing these welds.

2.

Where drilled holes are not accessible such as at

bottom of rocker panel, use 2.5 cm (1 inch) seam

welds spaced 7.5 cm (3 inches) apart to secure

rocker panel to sill side inner panel.

Fig. 48. Using MIG Welder For Plug Welds

3.

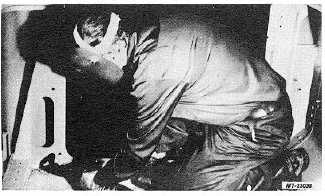

At inside of cab weld base of inner side panels to sill

side inner panel (Fig. 49). Note: 80" wide cabs do not

use a seam weld at cowl seam joint but have a panel

extension on sill side inner panel to be plug welded to

inside of side panel.

Fig. 49. Seam Weld At Inside Of Side Panel

CTS-2714R Page 27

PRINTED IN UNITED STATES OF AMERICA

|