|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

Driven Clutch Members

Two identical driven clutch members are

located on either side of the spider and center cam

assembly. Each has a set of clutch teeth to match the

clutch teeth on the spider through which driving torque is

transmitted. Radially inward from the driven clutch

teeth on models using internal spring are cams which

mesh with the cams of the center cam member. These

cams have been eliminated on the models using the

external spring. The internal diameter of each driven

clutch member has splines which engage the external

splines of the splined side members.

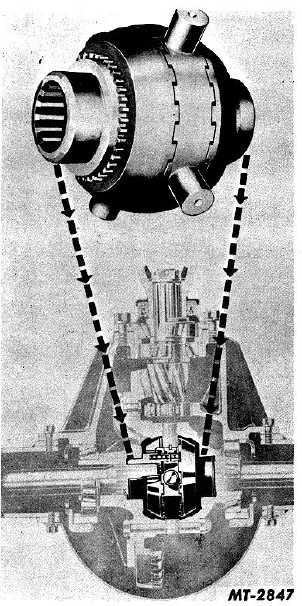

Fig. 36 Typical Installation of NoSPIN Unit

(Cross Sectional View)

Spring Retainers and Springs

Models with Internal Springs:

Spring retainers are inserted into the outer ends

of driven clutch member. The bowl side of these

retainers is mounted first through the outer side of the

driven clutch members. The flanged portion of the

spring retainers pass through the internal splines to rest

on the mating flanges of the driven clutch members.

The springs are mounted in spring retainers after

assembly and thrust against their inner cupped ends.

Models with External Springs:

Spring retainers fit over the side gear, passing

through external splines to seat against the shoulder on

the side gear. Springs fit between the driven clutch and

outer flanged surface of the spring retainer. Splined

Members These two splined side members are splined

internally to receive the truck axle shafts. The inner

hubs of the splined side members are inserted in the

outer ends of the springs. The external splines of the

splined side rembers engage the internal splines of

driven clutch members on each side of the completed

assembly.

OPERATION

Straight Forward Driving

When a vehicle is being driven in a straight

forward direction, the clutch teeth on both sides of the

spider assembly are fully engaged with the clutch teeth

on each driven clutch member. Likewise, the fixed

cams of the driven clutch members are fully meshed

with the cam surfaces of the floating center cam ring

mounted on the inside diameter of the spider, as

described previously.

Engagement of the driving and driven clutch

teeth is assured by the pressure of the two springs which

force the driven clutch members inwardly against the

spider and also by the positive locking action developed

by the mating undercuts on the driving faces of the

clutch teeth, Fig. 37.

In this condition, both clutches remain fully

engaged so that the assembly operates as a solid unit

and each rear wheel is driven forward at ring gear

speed.

CTS-2095S - Chapter II - Page 3

PRINTED IN UNITED STATES OF AMERICA

|