|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

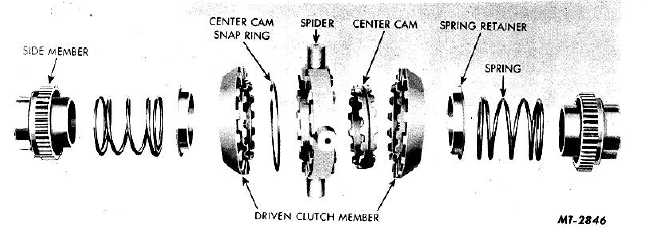

Fig. 34 Internal Spring Design differential Locking Unit (Exploded View)

DESCRIPTION

The NoSPIN differential (Figs. 34 and 35)

provides equal amounts of drive line torque to each rear

driving wheel and also permits differential action for

turning corners.

This differential also provides greater operating

flexibility than a conventional differential, because the

locking type differential overcomes wheel spinning when

required to operate in mud, sand, snow and on ice or

wet roads. The unit is installed in the differential case in

place of the conventional gears, pinion and spider. The

action of the unit is the same for both drive and coast

loads and forward and reverse driving.

CONSTRUCTION

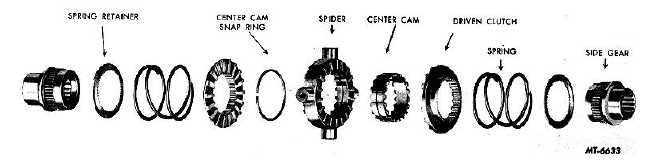

Two types of NoSPIN differentials have been

used on IH vehicles; they are (a) Internal Spring Design,

Fig. 34, and (b) External Spring Design, Fig. 35.

The difference in the two units is explained in

the text; however, the disassembly will cover the

internal design locking unit.

The differential locking unit consists of several

parts, all assembled around the spider.

Spider and Center Cam Assembly

This assembly consists of the spider, center

cam and spider snap ring. The spider has four trunnions

projecting radially from a center ring on each side of

which are located fixed driving clutch teeth. These teeth

vary in number, depending on the size and model of

differential. The internal diameter of the spider is

uniform. Into it is mounted the center cam. This cam is

held in position with a centrally mounted snap ring,

which permits the center cam to be rotated within the

spider but prevents lateral movement. The center cam

is symmetric, having the same number of cam lifts on

each side as there are clutch teeth on the spider. These

lifts or "cams" have uniform contours with rounded

surfaces that provide anti-friction ramps for disengaging

the driven clutch members.

Fig. 35. External Spring Design Differential Locking Unit (Exploded View)

CTS-2095S - Chapter II - Page 2

PRINTED IN UNITED STATES OF AMERICA

|