|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

SET GEAR LASH

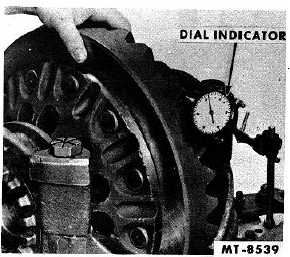

A special effort should be made to set the

backlash between pinion and ring gear to the same

amount as was originally built into them, 0.1-0.15 mm

(.004 to .006) on small gears or 0.15-0.2 mm (.006 to

.012) on larger gears. Generally the amount of backlash

is stamped or etched on the ring gear, Fig. 25. When

installing new gears, backlash is measured with a dial

indicator mounted on differential housing, as in Fig. 29.

To adjust the backlash, move the ring gear toward or

away from the pinion by means of the differential

bearing adjusting nuts.

Fig. 29 Using Dial Indicator to Set Correct

Backlash

Fig. 30 Right and Wrong Adjustment of Ring Gear and

Pinion When Worn Gears Are Reinstalled

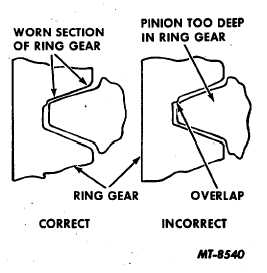

When original gear and pinion sets are being

reinstalled, the wear pattern of the gear teeth must be

considered in the backlash adjustment. Gears that have

been in service for long periods form running contacts

which should not be greatly changed. If, in checking

backlash, the amount measured is in excess of the

amount shown on the ring gear, the lash may be

reduced only in the amount that will avoid overlap of the

worn tooth section, Fig. 30. A slight overlap at the worn

section will cause gear operation to be noisy and rough.

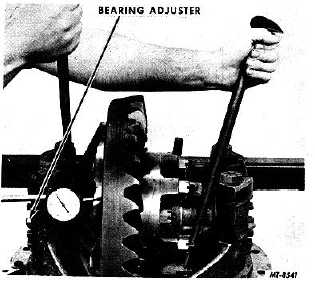

PRELOAD DIFFERENTIAL BEARINGS

After the ring gear has been adjusted for

position, another adjustment, the differential bearing

preload, is also accomplished by these same differential

bearing adjusting nuts. To set the preload, mount dial

indicator at side of ring gear, Fig. 31, and continue the

adjustment as follows:

Fig. 31 Adjusting Differential Bearing Preload

1. With the side bearing cap capscrews loosened

to permit bearing movement, loosen adjusting

nuts only enough to notice end play on

indicators.

2. Tighten adjusting nuts only enough to obtain .

000" end play reading on indicator. NOTE:

While gear is held in .000" end play and before

loading bearings, check gear for runout by

revolving ring gear. If runout exceeds 0.2 mm

(.008"), remove differential and check for cause.

3. Tighten both adjusting nuts from . 000" end

play to preload the differential bearings.

Tightening nuts one notch each usually gives

bearings the correct preload.

CTS-2095S - Chapter I - Page 13

PRINTED IN UNITED STATES OF AMERICA

|