|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

4. Tighten bearing cap capscrews or stud nuts to

specified torque.

5. Recheck gear lash to make certain that the lash

setting has not been changed during the

preloading operation.

6. Install adjusting nut locks.

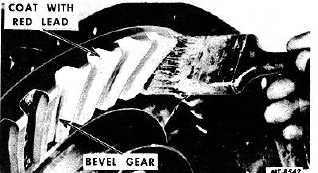

CHECK GEAR TOOTH CONTACT

The following instructions cover the paint

impression method of checking tooth contact and are

especially for the benefit of those not equipped with an

SE-1065 pinion setting gauge. The instructions may

also be used as a check on the adjustment obtained with

the gauge. By this method the mechanic temporarily

bolts up the pinion and cage to the differential carrier

and coats the drive gear teeth with oiled red lead, as in

Fig. 32. When the pinion is rotated, the red lead is

squeezed away by the contact of the teeth, leaving bare

areas the exact size, shape, and location of the

contacts. If these contacts are not acceptable, shims

must be added to or taken from the shim pack located

between the pinion cage flange and differential carrier

housing. In this manner, a satisfactory adjustment is

accomplished. Bear in mind that the accuracy of the

adjustment obtained with the paint impression method is

dependent upon the skill and experience of the

mechanic. It may be necessary to make several trials at

the right selection of shims to obtain the correct tooth

contact.

Fig. 32 Painting Gear Teeth for Obtaining

Tooth Contact Impressions

Sharper tooth contact impressions may be

obtained by applying a small amount of resistance to the

gear with a flat steel bar and using a wrench to rotate

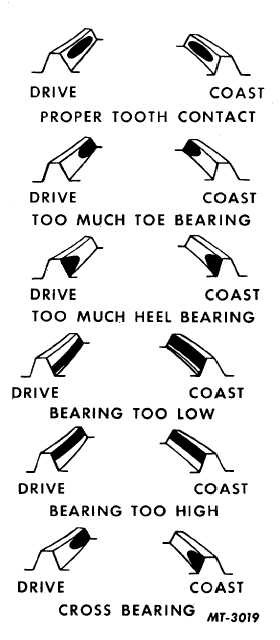

the pinion. When making adjustments, check the drive

side of the ring gear teeth. Coast side contact should be

automatically correct when drive side contact is correct.

As a rule, coating about twelve teeth is sufficient for

checking purposes.

Fig. 33 Location, Size and Shape of Correct Tooth

Contacts

With adjustments properly made, a correct tooth

contact similar to that shown in Fig. 33 will be secured.

The area of contact starts near the toe of the gear and

extends about 62-1/2 percent of the tooth length. This

adjustment results in a quiet running gear and pinion

CTS-2095S - Chapter I - Page 14

PRINTED IN UNITED STATES OF AMERICA

|