|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

lugs on step plate straddle the bearing staking indentations on

end of pinion.

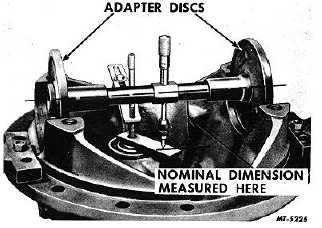

Fig. 27 Installing Step Plate

4.

Mount assembled SE-1065 gauge in bearing bores of

carrier as shown in Fig. 28. Make certain that bearing bores

are clean and free of nicks and burrs. Adjust micrometer so it

is directly over end at a 90 degree angle to the step plate.

Take micrometer reading. Run the micrometer thimble down

to measure the distance between the center of the ring gear

and the step plate, or in the event of a spiral bevel type drive,

measure the distance to the face of the pinion itself. Make a

note of this measurement.

Fig. 28 Assembled Gauge in Position

5.

Locate pinion nominal dimension (cone center

specification) for the axle to be adjusted. On some

axles this dimension may be shown on the pinion.

Where this is not the case, it will be listed in the rear

axle specifications. Write down this specification.

6.

Also locate on pinion the etched marking which

indicates a variation from zero cone center. If a

minus figure, subtract from specified cone center,

and if a plus figure, add to specified cone center.

NOTE

The plus or minus variation marked on the

pinion

will

not

necessarily

show

small

variations such as -5, +3, or +7. On some

pinions the variation marking will range to

higher figures such as +56, +59 or perhaps

higher.

Results of calculation give the corrected cone center

or pinion nominal dimension to which the pinion must be set.

7.

Comparison of corrected cone center (6) with the

actual or measured cone center (4) indicates amount

of change necessary for pinion position.

8.

Remove gauge and install ring gear and differential

carrier in the differential housing.

9.

Adjust backlash according to marking on ring gear.

To further clarify the use of the SE1065 pinion setting

gauge, the dimensions from the same type of axle as used in

the aforementioned disassembly will be used as an example

of the calculation involved.

Data:

Rear Axle Model-RA20

Rear Axle Code-14020

SE-1065-9 Adapter Disc-N (2)

Pinion Nominal Dimension-2.9839

Pinion Marked-(-5)

Procedure:

(a) Take micrometer reading with gauge .................... 2.6239

Add .400 for thickness of step plate ............................ +.4000

Equals - Measured Nominal Dimension....................... 3.0239

(b) Record Pinion Nominal Dimension from Specifications or

stamped on pinion ................................ ...................... 2.9839

Subtract the Pinion Correction

(-5) ................................ ................................ ............. -.0050

Equals - Corrected Nominal Dimension or distance pinion

should measure from center of ring gear..................... 2.9789

(c) Subtract correct Nominal Dimension (b) from actual

measurement (a)

Equals - Amount pinion must be moved in .................. 0.0450

CTS-2095S-CHAPTER I-Page 12

PRINTED IN UNITED STATES OF AMERICA

|