|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

AXLES-FRONT

Remove the friction shoe spring (3) as shown in Fig.

17. Friction shoes (4) may now be lifted out of roller cage (9).

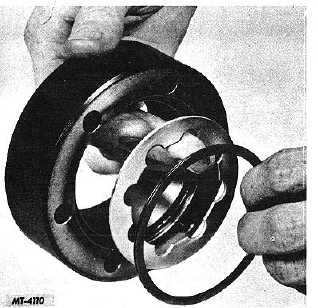

Fig. 18. Removing Spirolox Lock Ring and Thrust Washer

Remove the Spirolox lock ring (15) and thrust washer (13)

from the hub body (6). See Fig. 18.

Clutch Body (Lock-O-Matic)

Disassembly of the Lock-O-Matic clutch body is

identical to that of the manual type. Therefore, refer to the

disassembly procedure outlined under "Clutch Body (Manual

Type)" when disassembling the Lock-O-Matic hub.

CLEANING, INSPECTION AND REPAIR

Thoroughly wash all parts of the locking hub using a

good cleaning solvent. Dry all parts with compressed air or a

clean, lint-free cloth.

Inspect all parts for wear or damage. Check needle

bearings, rollers, axle shaft hub and hub body for pits or

cracks. Splines of axle shaft hub and clutch ring should be a

free sliding fit. If splines are worn or damaged, these parts

should be replaced. Use all new O-ring seals and gaskets

during reassembly.

REASSEMBLY

Hub Body (Manual Type)

If hub body needle bearing has been removed, install

new bearing being careful not to damage it.

Place axle shaft hub (4) into hub body (3) as shown

in Fig. 7. Secure axle shaft hub (4) in body (3) by installing

snap ring (1) in groove in end of axle shaft hub.

Clutch Body (Manual Type)

Apply a small amount of chassis lubricant on the

bearing side and in the grooves of the control assembly (16).

Install new O-ring seals (10 and 17) on control assembly (16).

If the hub has a seal groove, position the split towards the

outside of dial. Place disc (9) on inside (clutch side) of clutch

body (13). See Fig. 10.

Assemble clutch screw (8) into clutch ring (6) from

back side (Fig.8). Be certain clutch screw works freely. If it is

sticky in any position, tap lightly from the back side. Drop in

clutch ring and screw assembly. NOTE: Clutch screw (8)

should be flush with the back edge of clutch ring (6). Insert

the twelve drive pins (11). Try clutch ring for a free sliding fit

on drive pins. If it doesn't move freely from top to bottom, lift

out clutch ring and screw assembly and turn it to another

position. If it still does not move freely, it should be removed

and the clutch ring (6), clutch body (13) and drive pins (11)

examined for damage.

Apply a light grade chassis lubricant to the inside

face of the clutch body (13) and disc (9) from the front side of

the clutch body./ NOTE: Hold hand over drive pins to prevent

their falling out.

Position control assembly (16) with dowel pin (20)

into face of clutch body (13) so the arrow stops on the dot

marked "FREE." Install and tighten the flat head screw (7)

into the control assembly (16). NOTE: If screw (7) was

damaged during disassembly, it should be replaced.

To check clutch screw setting, turn control assembly

(16) from "LOCK" to "FREE" position and back several times.

Control assembly should "snap" into both positions. In

"FREE" position clutch ring (6) should just clear bottom of

clutch body (13).

NOTE: If clutch ring is set too far above

bottom of clutch body when set in the "FREE"

position, axle shaft hub (4) will rub face of

clutch ring.

Stake dowel pin (20) and flat head screw (7).

Turn control assembly (16) to "FREE" position and

apply a thin coating of light grade chassis lubricant around the

clutch screw (8) and drive pins (11).

CTS-2209-H Page 8

PRINTED IN UNITED STATES OF AMERICA

|