|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

19.

Run micrometer thimble down to measure distance

between center of ring gear and step plate. Make a note of

this reading along with the nominal dimension given in

"SPECIFICATIONS". Locate on pinion the etched marking

which indicates variation from zero cone setting. If it is a

minus figure, subtract it from specified dimension, and if a

plus figure, add it to specified dimension. Results of

calculation

will

provide

the

corrected

pinion

nominal

dimension to which pinion must be set. Comparison of

corrected nominal dimension with the actual or measured

dimension indicates amount of change necessary for correct

pinion position. It may be necessary to add or remove shims

between cage and differential carrier to provide correct pinion

nominal dimension.

20.

Remove gauge and prepare to install ring gear and

differential carrier in differential housing.

21.

If drive gear was removed from case, rivet gear to case

flanged half.

When reinstalling ring gear, it is suggested that

Riveting Jig SE-1575 be used. This special tool is

designed for use with either hydraulic or mechanical

press equipment. Rivet pressures for ring gear

installation should be in accordance with those given in

"SPECIFICATIONS".

22.

Apply axle lubricant to differential case inner walls and

all other component parts.

23.

Place thrust washer (25) and side gear (26) in flanged

half of case together with spider (27), pinion gears (28) and

thrust washers (29).

24.

Install opposite side gear and thrust washer in

differential case plain half (24).

25.

Align the match marks and join the two differential case

halves. Draw assembly together with four equally spaced

bolts (23) and nuts (33).

26.

Check assembly for free rotation of side gears and

pinions and if satisfactory, install remaining differential case

bolts. Tighten to torque specified in "TORQUE CHART".

27.

Differential bearings (22) are installed by pressing them

squarely onto differential case halves.

28.

Prelubricate differential bearings with axle lube and

place bearing cups (21) over

bearings. Attach chain sling to differential assembly and

install in carrier.

29.

Place bearing adjusters (14) in carrier and turn hand

tight against bearing cups (21).

30.

Observe match marks on bearing caps and install caps

onto legs of differential carrier (20).

31.

Install bearing cap bolts(17) and washers. Tighten to

specified torque. (See "TORQUE CHART".)

32.

Tighten bearing adjusters (14) alternately until all end

play is eliminated. Rotate differential while tightening.

Gear Lash

33.

A special effort should be made to set the backlash

between pinion and ring gear to the same amount as was

originally built into them .15-.30 mm (.006" to .012").

Generally the amount of backlash is stamped or etched on the

ring gear. When installing new gears, backlash is measured

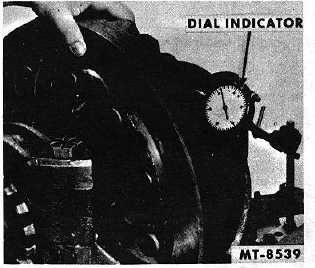

with a dial indicator mounted on differential housing (Fig. 16).

To adjust the backlash move the ring gear toward or away

from the pinion. This is done by backing off one adjusting

ring and advancing the opposite ring the same amount.

Fig. 16 Setting Correct Backlash

34.

When original gear and pinion sets are being

reinstalled, the wear pattern of the gear teeth must be

considered in the backlash adjustment. Gears that have been

in service for long periods form running contacts which should

not be greatly changed. If, in

CTS-2658S Page 9

PRINTED IN UNITED STATES OF AMERICA

|