|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

12.

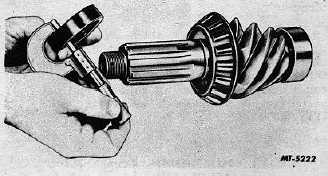

Wash spacer clean of emery cuttings before installing

on pinion.

Fig. 12 Measuring Spacer Thickness

13.

After pinion bearing preload is established good

practice would be to check bearing roller ends to see whether

they are in contact with bearing cone face. Use a feeler

gauge ribbon. There must be no clearance at ends of rollers

(Fig. 11).

Check pinion end nut for correct torque and install

cotter pin.

Pinion Nominal Dimension

To establish pinion nominal dimension which is the

distance from the face or finished end of the installed pinion to

the centerline of the ring gear or cross shaft, proceed as

follows.

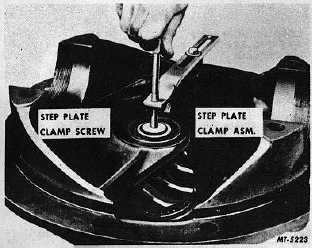

Fig. 13 Locating Step Plate Clamp

14.

Install pinion, cage and bearing assembly in differential

carrier. Obtain step plate clamp assembly from SE-1065

Pinion Setting Gauge set and attach it to differential carrier

flange, locating step plate clamp screw over center of pinion

(Fig. 13).

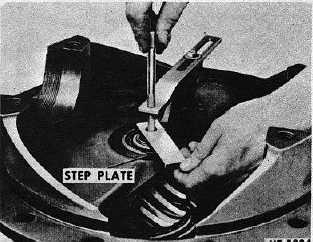

15.

Install step plate under clamp screw and tighten screw

to hold step plate securely in position (Fig. 14).

Fig. 14 Installing Step Plate

16.

The step plate is necessary to project the face of the

pinion where it can be measured by the gauge which is on the

centerline of the drive gear.

Be certain lugs on step plate straddle the bearing

staking indentations on end of pinion.

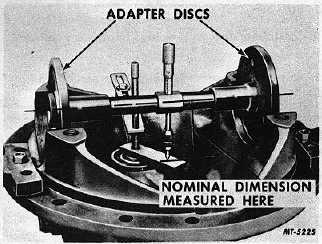

17.

Mount assembled SE-1065 gauge in bearing bores of

carrier (Fig. 15). See "SPECIFICATIONS" for correct disc

size.

Fig. 15 Assembled Gauge in Position

18.

Make certain that bearing bores are clean and free of

nicks and burrs. Adjust micrometer so it is directly over end

at a 90 degree angle to step plate.

CTS-2658S Page 8

PRINTED IN UNITED STATES OF AMERICA

|