|

| |

TM 5-4210-230-14&P-1

TRUCK SERVICE MANUAL

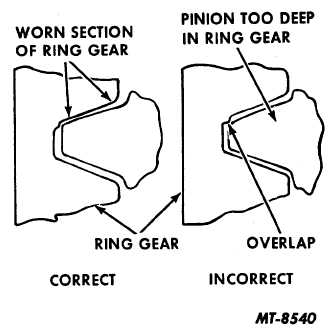

checking backlash, the amount measured is in excess of the

amount shown on the ring gear, the lash may be reduced only

in the amount that will avoid overlap of the worn tooth section

(Fig, 17). A slight overlap at the worn section will cause gear

operation to be noisy and rough.

Fig. 17 Correct and Incorrect Lash Adjustment where worn

Gears are Reinstalled

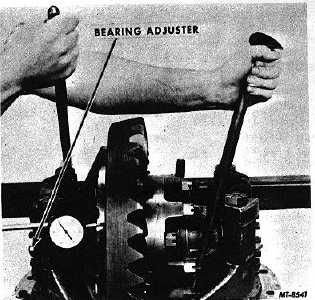

Differential Bearing Preload

35.

To set the bearing preload, mount dial indicator at side

of ring gear (Fig. 18). With the bearing capscrews loosened

to permit bearing movement, loosen adjusting nuts only

enough to notice end play on indicator.

36.

While gear is held in .000" end play and before loading

bearings, check gear for runout by revolving ring gear. If

runout exceeds 20 mm (.008"), remove differential and check

for cause. 37. Tighten both adjusting nuts from .000" end

play

to

preload

the

differential

bearings

(see

"SPECIFICATIONS").

38.

Tighten bearing cap, capscrews or stud nuts to

specified torque (see "TORQUE CHART").

39.

Recheck gear lash to make certain that the lash setting

has not been changed.

Fig. 18 Adjusting Bearing Preload

40.

Install adjusting rings locks and cotter pins.

Gear Tooth Contact

41.

Apply oiled red lead lightly to the hypoid gear teeth

(Fig. 19).

Fig. 19 Painting Gear Teeth for Obtaining Tooth Contact

Impressions

42.

When the pinion is rotated, the red lead is squeezed

away by the contact of the teeth, leaving bare areas the exact

size, shape and location of the contacts (Fig. 20).

43.

Sharper impressions may be obtained by applying a

small amount of resistance to the gear with a flat steel bar

and using a wrench to rotate the pinion. When making

adjustments, check the drive side of the gear teeth. Coast side

should be correct when drive side is correct. Generally,

coating approximately

CTS-2658S Page 10

PRINTED IN UNITED STATES OF AMERICA

|