|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

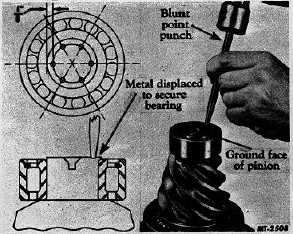

Fig. 9 Staking Pinion Straddle Bearing

It is suggested that for locating punch' positions

for staking, the end of the pinion be painted with

Prussian Blue and a circle be scribed on end of pinion

about 3.17 mm (1/8") in from the pinion circumference.

When staking the bearings be careful to make the

depth of the indentations or stake points uniform,

otherwise bearing may be damaged. Deep punch or

stake marks are not necessary. Apply the staking

operation at opposite sides of the pinion end until all

stake points are obtained. Where special staking tools

are available, they can be used, otherwise the use of a

blunt or round nosed punch is satisfactory.

3.

If bearing cups (7) have been replaced, press new cups

firmly against shoulders of pinion cage (10).

4.

Prelubricate the bearings with gear lubricant.

5.

Position spacer (8) on pinion shaft and against rear

thrust bearing.

6.

Insert pinion and rear thrust bearing (6) in pinion cage.

7.

Mount pinion and cage in arbor press and place pre-

lubricated front thrust bearing (6) on pinion shaft. Press

bearing firmly and squarely against spacer.

Pinion Bearing Preload

Pinion

bearing

preload

is

established

by

selecting the correct size spacer (8) located between

the two pinion thrust bearings and tightening pinion end

nut to the specified torque (see "TORQUE CHART").

8.

Temporarily assembly the pinion, cage and

flange assembly, less oil seal and retainer. Clamp the

assembly in a vise to hold the companion flange. Tighten end

nut to specified torque.

9.

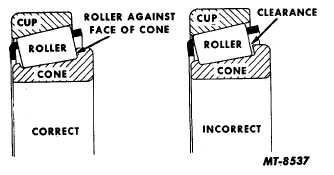

The pinion cage should be rotated while tightening the

pinion to seat and align the bearings. Rotation of the pinion is

important. Otherwise a false condition of bearing load could

exist. The bearing rollers must be seated against the face of

the bearing cone (Fig. 10).

Fig. 10 Pinion Bearing Roller Position

10.

To measure bearing preload, wrap a strong cord or soft

wire about the pinion cage and attach end to spring scale (Fig.

11). Read scale only while cage is rotating. Compare this

scale reading with the figure shown in "SPECIFICATIONS".

Fig. 11 Measuring Pinion Bearing Preload

11.

When

preload

does

not

agree

with

"SPECIFICATIONS", bearing load may be increased by

installing a thinner spacer or decreased by using a thicker

spacer. Determine spacer thickness using a micrometer (Fig.

12) and make a new selection accordingly. Closer adjustment

may be obtained by working spacer to desired thickness,

using emery cloth on a flat surface.

CTS-2658S Page 7

PRINTED IN UNITED STATES OF AMERICA

|