|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

WHEELS, RIMS, TIRES

2.

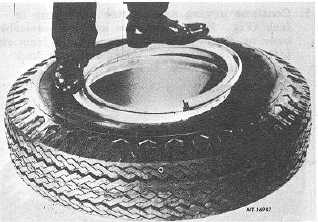

Continue "Walking" side-ring into place (Fig. 41). ,

Fig. 41

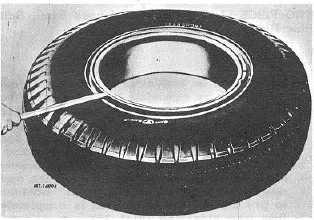

3. Check to insure that side-ring is fully seated in gutter as

shown in Figure 42.

Fig. 42

4.

Place tire assembly into safety cage and inflate to a

maximum of 10 psi using an extension hose with gauge

and clip-on chuck. Check side-ring by lightly tapping

with mallet to insure proper engagement. Inspect to

insure proper seating of beads. Completely deflate tire

to prevent tube from buckling. Reinflate to

recommended pressure.

THREE-PIECE FLAT BASE

Dismounting:

1.

Remove valve core and completely deflate the tire or

both tires if working on duals before removing the tire

and rim assembly from the truck. Remove tire

assembly from truck and place on floor with the side-

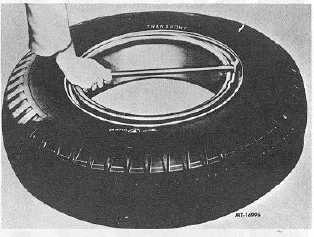

ring up. Insert

tapered end of rim tool into depression in lock ring, or

between rings, and press down on side ring to free bead.

Continue around tire until the bead is completely freed from

the bead seat (Fig. 43).

Fig. 43

2.

Insert rim tool into removing notch, near split in the ring

and push downward to remove lock-ring from rim

gutter. A second rim tool may be helpful to aid in

removal (Fig. 44).

Fig. 44

3.

Insert rim tool between lock-ring and sidering. Press

down to pry ring up and continue around rim until lock-

ring is free (Fig. 45). Remove lock and side-rings from

rim. Turn assembly over, unseat second tire bead,

stand tire up and remove rim base.

CTS-2032N Page 14

PRINTED IN UNITED STATES OF AMERICA

|