|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

WHEELS, RIMS, TIRES

4.

Check valve to be certain that hex nut at the base is

tight; also check valve core to make sure that no air

loss can occur. Stand tire in a vertical position and

inflate to recommended air pressure.

TWO-PIECE FLAT BASE (Continuous Base, Split Side-Ring)

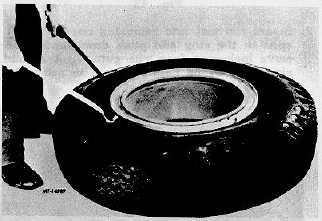

Dismounting:

1.

Deflate tire or both tires if working on duals completely

by removing the valve core, before removing tire and

rim assembly from truck. Remove tire from truck and

place on floor with the side-ring up. Pry bead loose

from side-ring by inserting curved end of rim tool and

hooked-end of rim tool between side-ring and side-wall

of tire. Then apply downward pressure on rim tools.

Continue to pry around tire until bead is completely free

from side-ring (Fig. 37).

Fig. 37

Fig. 38

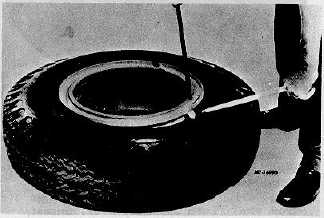

2.

Insert tapered end of tool into notch on sidering, pry

ring upward and outward to remove side-ring from its

groove in rim. Place hooked-end of tool between the

ring

and tire. Pry upward on ring and downward on tire to free ring

from tire bead (Fig. 38).

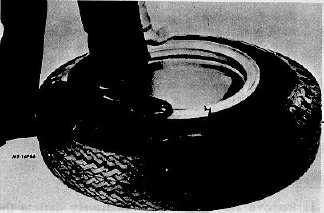

3.

Continue prying around tire until ring is free (Fig. 39).

Turn tire and rim assembly over on floor. Unseat

second bead from rim. Lift the rim from tire. Remove

tube and flap, if used, from tire.

Fig. 39

Mounting:

1.

Place tube and flap into tire and partially inflate to

round out tube. Apply approved rubber lubrication to

inside and outside surfaces of both beads and also to

the portion of tube and flap that appears between

beads. With valve slot up place rim flat on floor. Align

valve with rim valve slot, place tire on rim and insert

valve through valve slot. Place side-ring on rim base

with ring split opposite the valve stem. Install leading

end of ring into gutter of rim (Fig. 40).

Fig. 40

CTS-2032N Page 13

PRINTED IN UNITED STATES OF AME RICA

|