|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

WHEELS, RIMS, TIRES

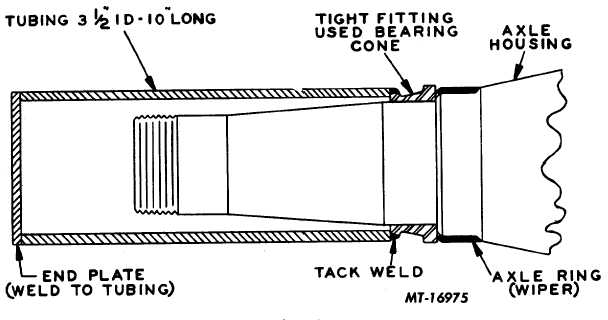

Fig. 5

OIL SEAL INSTALLATION

(OIL SEAL WITH AXLE RING)

1.

Remove burrs from inside back edge of hub. Hub must

be smooth and free from burrs that will scratch the hub

seal.

2.

Apply a thin coat of Permatex No. 2 around the

outside perimeter of hub seal. Permatex coating must

be very light yet cover press fit area. Remember that

Permatex is abrasive and should never be allowed to

contact lip of leather seal nor contaminate oil.

3.

Lay wheel flat with brake drum up. Place inner wheel

bearing into bearing cup and place hub seal into

starting position on hub.

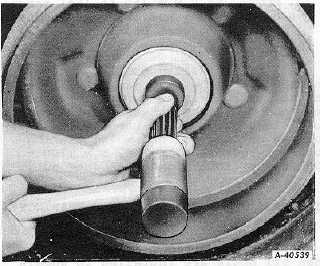

4.

Install hub seal using SE-1904 Installer Set (Fig. 6).

Select the size disc which will apply force to outer edge

of hub seal and prevent seal from becoming distorted

or damaged.

5.

Drive hub seal into hub until it bottoms in hub bore. Do

not continue to drive after seal is once seated as this

will distort or damage the seal. After removal of seal

installer tool, clean off excess Permatex (for proper

installation, note Fig. 7).

UNITIZED OIL SEAL

(AXLE RING NOT REQUIRED)

Unitized oil seals do not require axle rings (wipers) and

minimize wear on the axle spindle as follows. The outer shell

of the seal being pressure fit in the wheel hub rotates with the

wheel around the sealing element which is pressure fit on the

axle spindle. With the unitized seal when replacement is

made, the worn surface created by the sealing lip is also

replaced.

Fig. 6

CTS-2032N Page 4

PRINTED IN UNITED STATES OF AMERICA

|