|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

WHEELS, RIMS, TIRES

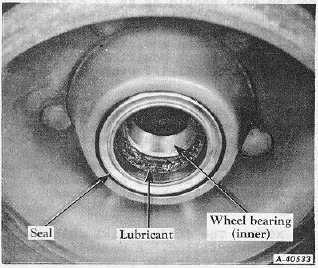

Fig. 7

Unitized Seal Installation

1.

If wheel is being changed to a unitized seal from

another type of seal, remove wear sleeve backing

plates or axle rings as they are no longer required.

Note the order of parts at disassembly to assure proper

reassembly.

2.

Thoroughly clean all parts and remove all burrs from

spindle and hub bore. Inspect and replace all parts as

warranted.

3.

To install unitized seal in wheel, seat outer face of seal

in the recess of tool adapter SE-2524 (Fig. 8). Insert

centering plug of tool in bore of inner bearing cone (Fig.

9). Using the centering plug prevents cocking of the

seal in wheel bore. Bore-tite coating on seal fills in

minor imperfections in the wheel bore.

Fig. 8

Fig. 9

4.

Hold tool handle firmly and strike until sound of impact

changes when seal is seated (Fig. 10).

NOTE: Seal must be reseated any time wheel

is removed.

A good check of proper seal installation is to move the

synthetic sealing member with your fingers after installation in

wheel hub. There should be a slight in and out movement

possible.

Fig. 10

MOUNTING WHEEL ON SPINDLE INSTRUCTIONS

(With Oil Lubricated Bearings)

1.

To insure good starting lubrication fill wheel cavity

between the bearings with lubricant.

Front Axle: Fill wheel cavity with engine oil or rear

axle lubricant (see LUBRICATION, Section CTS-

2412).

Rear Axle: Fill with same gear lubricant as used in

the axle differential.

CTS-2032N Page 5

PRINTED IN UNITED STATES OF AMERICA

|