|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM5-4210-224-14&P

4-209. BRAKE SYSTEM PIPES AND HOSES REPLACEMENT. (Continued)

CAUTION

Never use copper tubing for

hydraulic brake lines because

copper is subject to fatigue,

cracking and corrosion which result

in brake failure.

NOTE

When replacing a steel brake pipe,

always use steel piping which is

designed

to

withstand

high

pressure and resist corrosion. The

same size pipe must be used as

the one removed. The outside

diameter of the pipe is used to

specify the size.

Brake pipes that run parallel to each

other must maintain a 1/4 inch (6

mm) clearance.

c. After flaring, blow out the brake pipe with

compressed air before installing on the vehicle.

When installing pipe, a special

d. Bend the pipe to match the configuration of the

double-lap flaring tool must be

old pipe by using a pipe bender.

used, as single flaring tools cannot

produce a flare strong enough to

e. Attach the pipe to the rear brake drum hose.

hold the necessary pressure. When

using the tool, be sure to follow the

NOTE

instructions furnished by the tool

The hose must not be twisted

manufacturer. Be sure to inspect

newly formed flares for cracks or

malformations which might cause

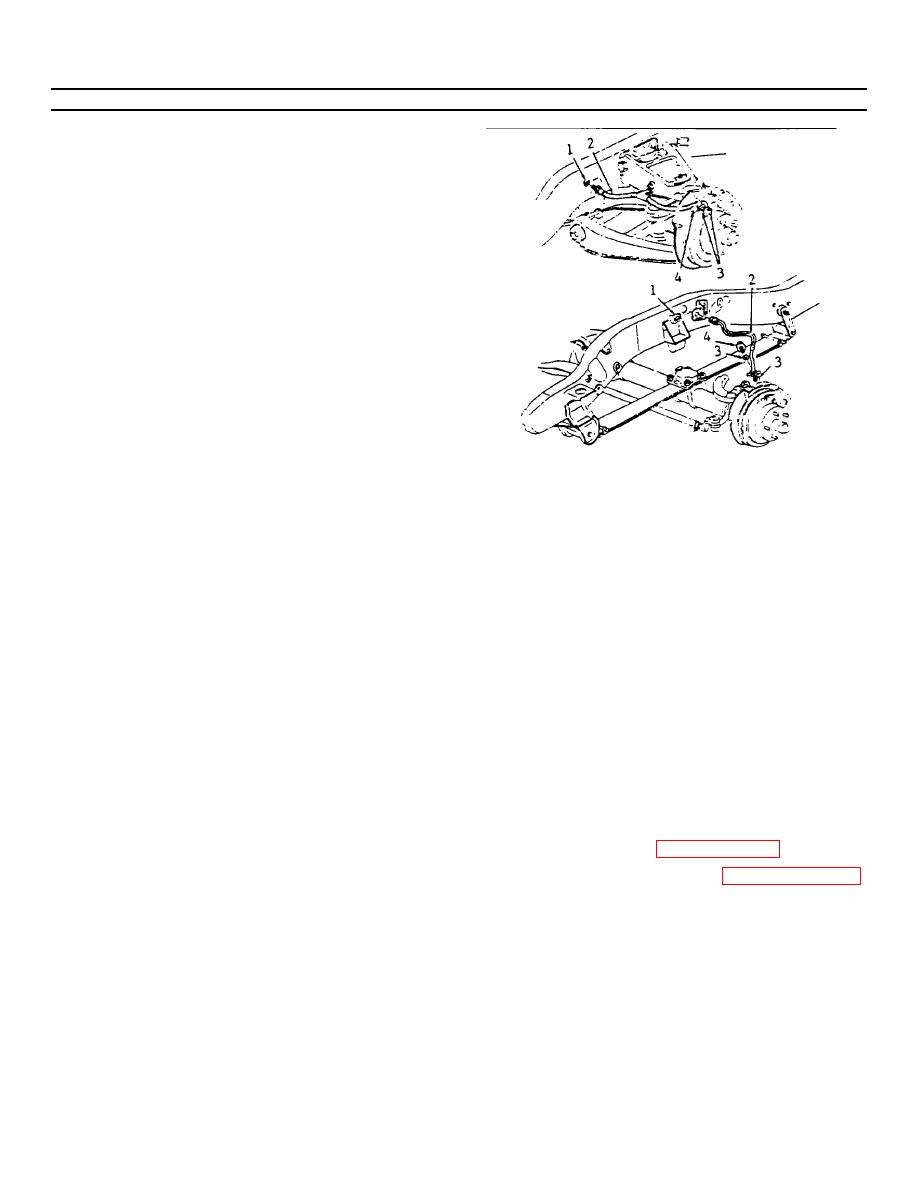

f. Using new copper washers (3), install the pipe

leaks.

and hose (2) with new washers (3) to the drum.

a. Cut the pipe with the tube cutter to length. Add

g. Install the other end of the hose (2) to the frame

1/8 inch (3mm) to the length for each flare.

with the nut or clip (1).

b. Flare the pipe ends by following the instructions

h. Install the front brake hose (2) to the caliper with

provided by the double lap flaring tool

the bolt (4) and new copper washers (3).

manufacturer.

i. Install the other end to the frame with nut or clip

(1).

WARNING

Compressed air used for cleaning

j. Bleed the brakes (paragraph 4-208).

or drying can create airborne

k. Install wheel assembly (paragraph 4-203).

particles that may enter the eyes.

Pressure shall not exceed 30 psi

(206 kPa). Wearing of goggles is

required to avoid injury to

personnel.

4-289

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |