|

|||

|

|

|||

|

Page Title:

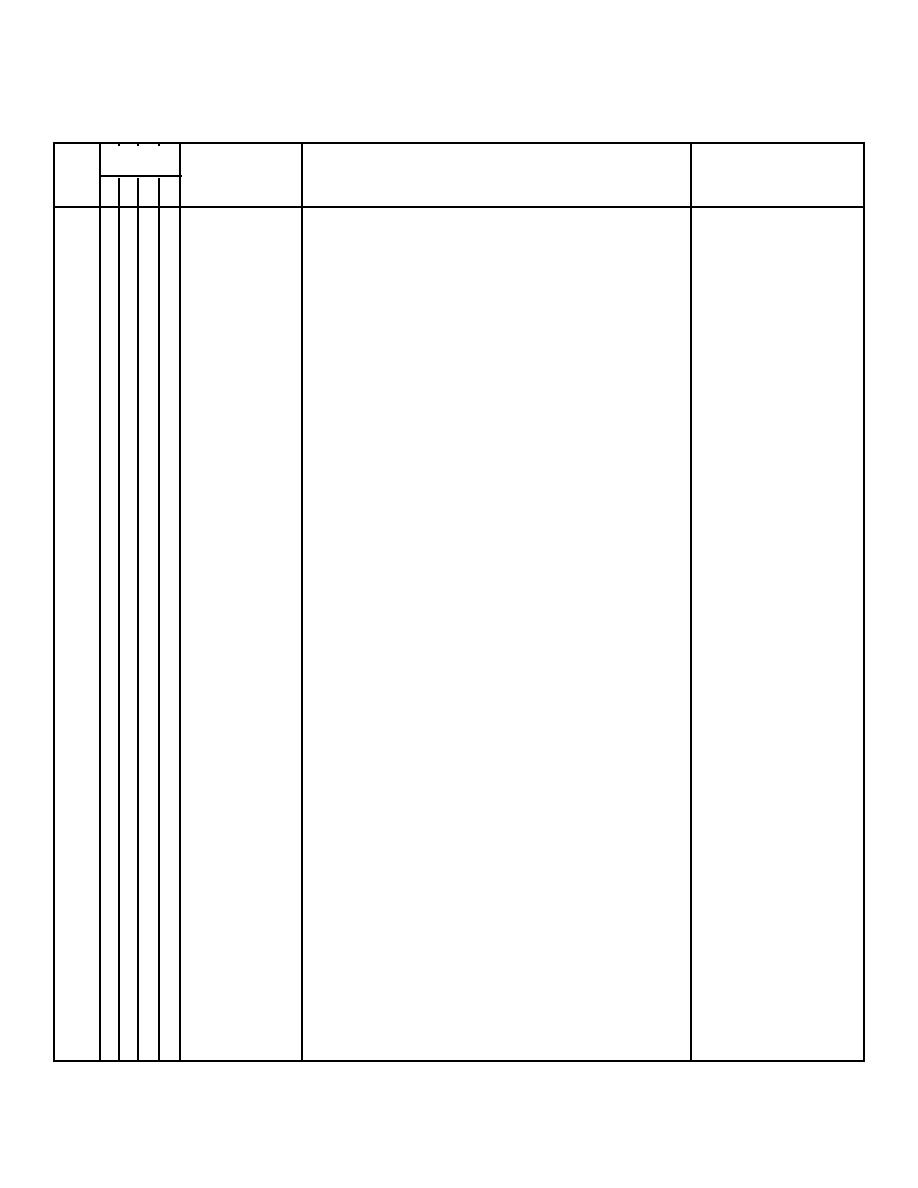

Table 2-5 Operator Preventive Maintenance Checks and Services - Continued |

|

||

| ||||||||||

|

|

TM 5-4210-224-14&P

Table 2-5 Operator Preventive Maintenance Checks and Services - Continued

D - Daily

W - Weekly

A-

After

M-

Monthly

PROCEDURES

EQUIPMENT IS

INTERVAL

ITEM

ITEM TO BE

Check for and have repaired

NOT READY/

NO. D A W M

INSPECTED

or adjusted as necessary

AVAILABLE IF

ENGINE COOLING SYSTEM

23

Fan and Drive

Visually inspect fan and drive belts for fraying,

Fan damaged.

qq

Belts

proper tension, and structural damage. Refer

Drive belts

to next higher level of maintenance for adjustment

worn. Not properly

or replacement.

tightened.

WARNING

24

Coolant Level

qq

Allow engine to cool 15 minutes before

removing filler cap.

Coolant level

Visually inspect coolant for rust or impurities.

is low.

Appearance of rust indicates that the corrosion

inhibitor has lost its effectiveness. Check

coolant level. Coolant level should be slightly

above the "COLD" mark on the recovery tank.

Refer to next higher level of maintenance for

service.

25

Radiator, Heat

Visually inspect radiator, heat exchanger, hoses

qq

Exchanger,

and piping for corrosion and structural damage.

Hoses and

Piping

26

Water Pump

Visually inspect water pump and connections for

Water pump is

q

corrosion and structural damage. Refer to next

damaged.

higher level of maintenance if any defects are

found.

ENGINE FUEL SYSTEM

27

q Air Cleaner

Visually inspect air filter filament for dirt,

corrosion, or damage.

28

q Fuel Line

Visually inspect fuel lines for damage or loose

and Filter

connections. Visually inspect filter elements

and exterior of fuel filter for corrosion or

structural damage.

29

Fuel Tank,

Visually inspect fuel tank, fill pipe, and cap for

Fuel tank is

q

Fill Pipe

corrosion or structural damage. Visually inspect

damaged.

and Cap

cap seals for deterioration. Refer to next higher

level of maintenance if any defects are found.

30

Fuel Pump,

Visually inspect fuel pump for corrosion and

Fuel pump is

q

structural damage. Refer to next higher level

damaged.

of maintenance if any defects are found.

DIESEL FUEL INJECTION SYSTEM

31

Injection

Visually inspect injection pump and injection lines

Injection pump

q

Pump and

for corrosion or structural damage. Refer to next

is damaged.

Lines

higher level of maintenance if any defects are

found.

2-37

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |