|

| |

TM 5-4210-220-34

2-12.

PUMP DRIVE AND PTO - Continued

(8)

Press the bearing caps (9) from the yoke

using the following procedures.

(9)

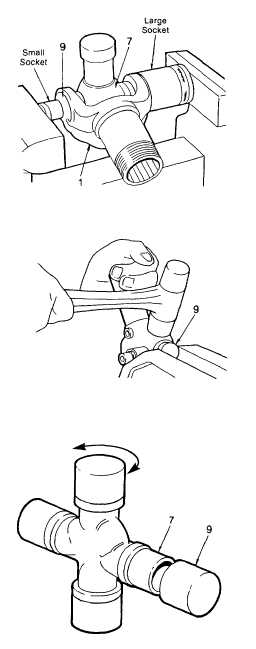

Position the slip joint yoke (1) between a

large socket and a small socket, and

between the vise jaws as shown.

(10) Close the vise. As the vise is closed, the

small socket will force the bearing cap (9)

into the cross (7) and in turn, the cross will

force the opposite bearing cap into the large

socket.

(11) The cross (7) travel is not enough to allow

bearing cap (9) to be completely removed.

Grasp the protruding bearing cap (9) in a

vise. Strike yoke as shown using a soft

faced hammer to completely remove bearing

cap.

(12) Remove opposite bearing cap similar to

steps 9 thru 11 preceding.

(13) Carefully maneuver the cross (7) from

between the yoke lugs.

(14) Remove the universal joint from between the

tight end yoke (2) and the flanged yoke (11)

following steps 8 thru 13 preceding. This

procedure will have to be carried out twice

for complete removal.

(15) Visually inspect exposed universal joint cross

(7) journals and needle bearings in bearing

caps (9). Look for defects caused by lack of

lubrication,

and

physical

damage.

If

corrosion, pitting, unusual wear or missing

needle bearings is evident, the complete

universal joint kit must be replaced. If no

damage is evident, continue inspecting.

WARNING

Dry

cleaning

solvent

P-D-680

(safety

or

Stoddard’s solvent) is potentially dangerous.

Avoid repeated and prolonged breathing of vapors

and skin contact with the liquid. Do not use near

open flame, arcing equipment or other ignition

sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is

100 to 138 deg. F (30 to 59 deg. C).

2-83

|